Top 10 shutter valve in China introduce,list main products and website if have

Here are the top 10 shutter valve manufacturers in China, including their main products and websites:

1. Chuanyi Automation – Specializes in automation control systems, intelligent field instruments, and various industrial valves. Website: [Chuanyi Automation](http://www.chuanyi.com)

2. Neway Valve – Offers gate valves, globe valves, check valves, ball valves, butterfly valves, and more, with significant innovations in high-end fields like deep-sea and nuclear power valves. Website: [Neway Valve](http://www.newayvalve.com)

3. Suyan Valve – Produces gate valves, ball valves, and fully welded ball valves, with a focus on the oil, natural gas, power station, ocean, nuclear power, and LNG sectors. Website: [Suyan Valve](http://www.suyangroup.com)

4. Xintai Valve Group – Known for stainless steel check valves, gate valves, globe valves, and butterfly valves, with advanced manufacturing bases and casting lines. Website: [Xintai Valve](http://www.xintaivalves.com)

5. Shanghai Valve Factory Co., Ltd. – Established in 1921, this company manufactures gate valves, ball valves, and butterfly valves, serving high-pressure and high-temperature applications. Website: [Shanghai Valve Factory](http://www.shvalve.com)

6. CNNC Sufa Technology Industry Co., Ltd. – Specializes in nuclear-grade valves, control valves, and safety valves for nuclear power plants. Website: [CNNC Sufa](http://www.cnnc.com.cn)

7. Huangshan Industrial Pump & Valve Co., Ltd. – Produces globe valves, check valves, and diaphragm valves for handling corrosive fluids. Website: [Huangshan Valve](http://www.hspv.com.cn)

8. China Valve Technology Co., Ltd. – Focuses on ball valves, butterfly valves, and plug valves, serving industries like oil and gas, chemical, and power generation. Website: [China Valve Technology](http://www.cvalve.com)

9. Zhejiang Zhedong Valve Co., Ltd. – Offers a variety of valves including gate valves, globe valves, and check valves with certifications like ISO 9001 and API 6D. Website: [Zhedong Valve](http://www.zhedongvalve.com)

10. Dervos Valve – Manufactures ball, gate, globe, and check valves, emphasizing quality control and serving industries such as oil, gas, and chemicals. Website: [Dervos Valve](http://www.dervosvalve.com)

These companies are recognized for their innovation, extensive product lines, and adherence to international standards, making them leaders in the shutter valve industry in China.

Types of shutter valve

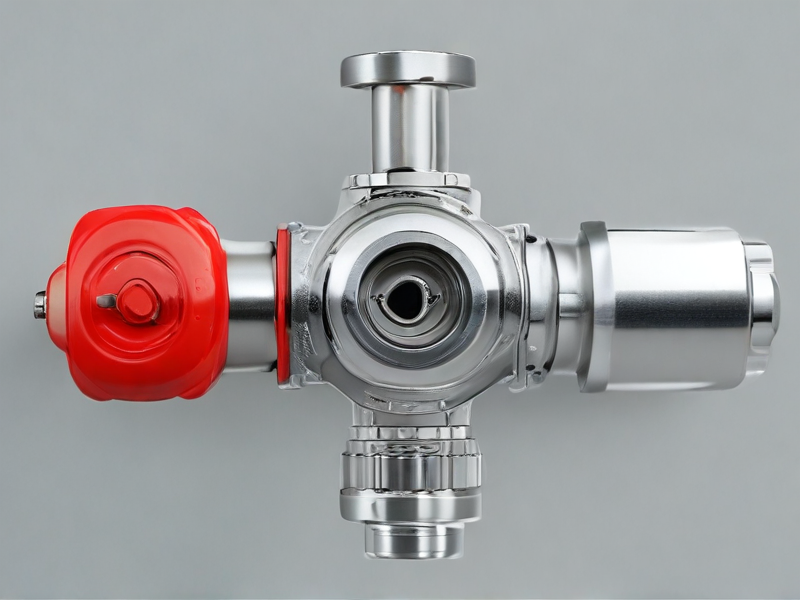

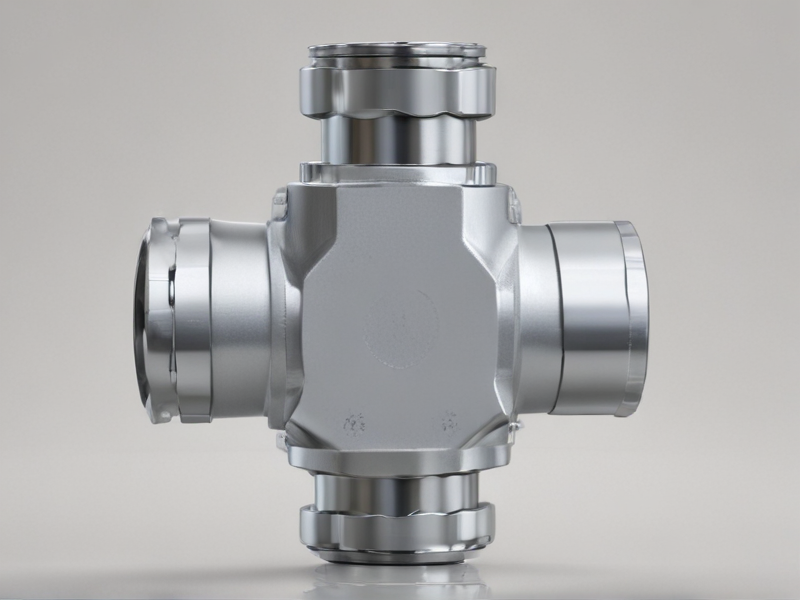

Shutter valves, commonly known as butterfly valves, are widely used in various industries for regulating and isolating flow. There are several types of shutter valves, each designed for specific applications and offering unique features.

1. Concentric Butterfly Valve:

– Design: The disc is centrally located in the pipe and rotates around a central axis.

– Usage: Common in water treatment and HVAC systems.

– Advantages: Simple design, low cost, and easy to operate.

2. Double-Eccentric Butterfly Valve:

– Design: The disc is offset from the centerline of the valve seat and the pipe.

– Usage: Suitable for high-pressure applications and where tight sealing is required.

– Advantages: Reduced friction during operation, leading to longer valve life and improved sealing.

3. Triple-Eccentric Butterfly Valve:

– Design: Features three offsets – two from the centerline and one from the seat, creating a cam-like motion.

– Usage: Ideal for high-temperature and high-pressure environments, such as steam services.

– Advantages: Minimal wear, excellent sealing properties, and capable of handling severe service conditions.

4. Lug Style Butterfly Valve:

– Design: Bolted between flanges with threaded inserts (lugs) on the valve body.

– Usage: Allows for one side of the piping system to be disconnected without affecting the other side.

– Advantages: Easy installation and maintenance, and can act as a shut-off valve.

5. Wafer Style Butterfly Valve:

– Design: Fits between two flanges and is held in place by the bolts of the pipe flanges.

– Usage: Common in lower-pressure applications.

– Advantages: Cost-effective, simple installation, and requires less space.

6. High-Performance Butterfly Valve:

– Design: Enhanced design features such as a double or triple offset, and advanced sealing materials.

– Usage: Suitable for demanding applications with high pressure and temperature.

– Advantages: Higher durability, reliability, and better performance under extreme conditions.

These various types of shutter valves cater to different operational needs, ensuring optimal performance across diverse industrial applications.

Pros and Cons of Using shutter valve

Pros and Cons of Using a Shutter Valve

Pros:

1. Precise Flow Control: Shutter valves allow for precise regulation of fluid flow, making them ideal for applications requiring accurate control.

2. Compact Design: These valves are generally smaller and more compact than other types, saving space in installations.

3. Durability: Shutter valves are built to handle high-pressure conditions and can be made from materials that resist corrosion, enhancing their longevity.

4. Quick Operation: They can be quickly opened or closed, which is beneficial in emergency shutoff situations or processes that require rapid adjustments.

5. Minimal Leakage: When properly installed and maintained, shutter valves have minimal leakage, ensuring system efficiency and safety.

6. Versatility: Suitable for various industries, including chemical, oil and gas, water treatment, and HVAC systems.

Cons:

1. Cost: Initial purchase and maintenance costs can be higher compared to simpler valve types, such as gate or ball valves.

2. Complex Installation: The installation process can be more complex and time-consuming, requiring skilled technicians.

3. Maintenance Requirements: Regular maintenance is needed to ensure optimal performance, which can increase operational costs.

4. Potential for Wear and Tear: Moving parts are subject to wear and tear, especially in abrasive or high-pressure environments, potentially leading to more frequent replacements.

5. Pressure Drop: There can be a significant pressure drop across the valve, which might affect the efficiency of the system in some applications.

6. Limited to Certain Fluids: Not all shutter valves are suitable for every type of fluid, particularly those with high particulate content, which can cause clogging or damage.

In conclusion, while shutter valves offer precise control and durability, their higher costs and maintenance needs must be weighed against their benefits for specific applications.

shutter valve Reference Specifications (varies for different product)

Shutter valves are essential components used to control the flow of fluids in various industrial applications. Here is an overview of the reference specifications that may vary for different products:

1. Size and Dimensions:

– Nominal Diameter (DN): Ranges from 50mm to 1200mm.

– Face-to-Face Length: Typically follows standards like ANSI, DIN, or JIS, with variations depending on specific application requirements.

2. Pressure Ratings:

– Maximum Operating Pressure: Commonly between 10 bar and 40 bar, with higher ratings available for specialized applications.

– Test Pressure: Often 1.5 times the maximum operating pressure for seat leakage tests.

3. Materials:

– Body: Typically made from cast iron, ductile iron, stainless steel, or carbon steel.

– Disc: Materials include stainless steel, aluminum bronze, or nickel-plated.

– Seat: Can be EPDM, NBR, PTFE, or metal, depending on the fluid and temperature conditions.

4. Temperature Range:

– Operating temperature usually spans from -20°C to 200°C, with higher or lower ranges available based on the material and design.

5. End Connections:

– Flanged: Conforming to standards such as ASME B16.5, EN 1092-1, or JIS B2220.

– Wafer: Designed to fit between flanges.

– Lug: Can be used as an end-of-line valve.

6. Operation and Actuation:

– Manual: Lever or gear-operated.

– Automatic: Pneumatic, hydraulic, or electric actuators, with options for positioners and feedback systems.

7. Flow Characteristics:

– Cv (Flow Coefficient): Specifies the flow capacity, varying based on valve size and design.

– Leakage Rate: Classed according to ANSI/FCI 70-2 standards, ranging from Class IV to VI for different sealing requirements.

8. Compliance and Certifications:

– Conformance to ISO, API, and other relevant standards for quality and performance.

– Certifications such as CE, ATEX, or SIL for specific industry needs.

These specifications ensure that shutter valves meet the demands of various industrial environments, providing reliable and efficient flow control.

Applications of shutter valve

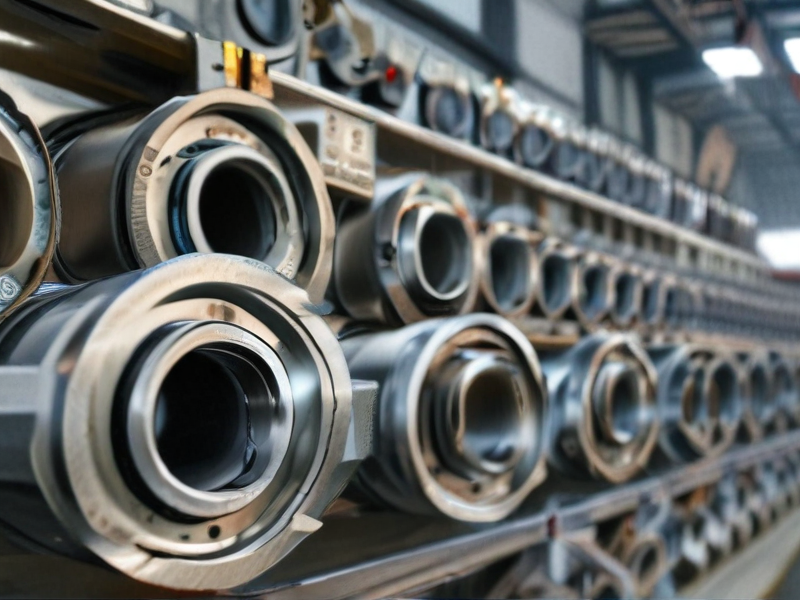

Shutter valves, also known as butterfly valves, are versatile components used across various industries for their efficiency in regulating and isolating flow. Here are some key applications:

1. Water Treatment Plants: Shutter valves are extensively used in water treatment facilities to control the flow of water and chemicals, ensuring proper treatment and distribution. Their ability to handle large volumes of fluid with minimal pressure drop makes them ideal for this application.

2. HVAC Systems: In heating, ventilation, and air conditioning systems, shutter valves manage the flow of air and coolant, contributing to energy efficiency and precise temperature control. Their compact design and quick operation are particularly beneficial in these environments.

3. Oil and Gas Industry: These valves are critical in the oil and gas sector for isolating and regulating the flow of crude oil, natural gas, and other petrochemical products. Their robust construction can withstand high pressures and harsh conditions commonly found in this industry.

4. Food and Beverage Processing: Shutter valves are used to control the flow of ingredients, water, and cleaning solutions in food and beverage production. Their design allows for easy cleaning and maintenance, which is crucial for hygiene and safety in this industry.

5. Chemical Processing: In chemical plants, shutter valves regulate the flow of various chemicals, ensuring precise control over reactions and processes. Their ability to handle corrosive and hazardous materials makes them a reliable choice for this application.

6. Power Generation: Power plants use shutter valves in cooling systems, fuel handling, and other critical applications. Their reliability and efficiency are essential for maintaining the continuous operation of power generation facilities.

7. Marine Applications: On ships and offshore platforms, shutter valves manage ballast water, fuel, and other fluids. Their corrosion-resistant materials and durable construction are vital for withstanding marine environments.

Overall, shutter valves are valued for their durability, ease of operation, and ability to handle a wide range of fluids, making them indispensable in many industrial processes.

Material of shutter valve

Shutter valves, also known as gate valves, are crucial components in fluid control systems, designed to start, stop, or regulate the flow of liquids and gases. The material selection for these valves is critical to ensure durability, reliability, and compatibility with the intended application.

1. Cast Iron: Commonly used for water distribution systems and low-pressure applications due to its durability, cost-effectiveness, and resistance to wear.

2. Ductile Iron: An improved version of cast iron with added flexibility and strength. It is suitable for applications requiring higher pressure resistance and impact tolerance.

3. Carbon Steel: Preferred for high-pressure and high-temperature applications. It offers excellent mechanical properties and is used in industries like oil and gas, petrochemical, and power generation.

4. Stainless Steel: Known for its corrosion resistance, it is ideal for harsh environments, including chemical processing and marine applications. Stainless steel valves are often used in applications where hygiene and resistance to aggressive media are crucial.

5. Bronze and Brass: Often used in applications involving water and steam. These materials offer good corrosion resistance and machinability, making them suitable for residential and light commercial plumbing.

6. Alloy Steel: Utilized in high-temperature and high-pressure environments. Alloy steels are designed to withstand extreme conditions, often used in the oil and gas industry.

7. PVC and Other Plastics: Used in low-pressure, non-corrosive environments like irrigation and residential plumbing. These materials are lightweight, cost-effective, and resistant to various chemicals.

8. Exotic Alloys (e.g., Hastelloy, Monel): Employed in highly corrosive environments. These specialized materials offer superior resistance to chemicals and are used in the chemical processing and pharmaceutical industries.

Selecting the appropriate material for a shutter valve depends on the specific application requirements, including pressure, temperature, and the nature of the fluid being controlled. Proper material selection ensures the valve’s longevity and efficient performance.

Quality Testing Methods for shutter valve and how to control the quality

Quality testing for shutter valves involves several methods to ensure they meet performance, safety, and reliability standards. Key methods include:

1. Visual Inspection:

– Purpose: Detect surface defects, corrosion, and manufacturing flaws.

– Process: Inspect valves visually for irregularities, cracks, or surface defects. Use magnification tools if necessary.

2. Dimensional Verification:

– Purpose: Ensure all dimensions meet design specifications.

– Process: Use calipers, micrometers, and gauges to measure critical dimensions against the design blueprint.

3. Hydrostatic Testing:

– Purpose: Verify pressure resistance and leak-proof performance.

– Process: Subject the valve to high-pressure water to check for leaks or deformations.

4. Pneumatic Testing:

– Purpose: Test for leaks under gas pressure conditions.

– Process: Pressurize the valve with air or inert gas and submerge it in water to detect escaping bubbles indicating leaks.

5. Functional Testing:

– Purpose: Assess operational performance.

– Process: Operate the valve through multiple cycles to ensure it opens and closes smoothly and responds correctly to control inputs.

6. Non-Destructive Testing (NDT):

– Purpose: Identify internal flaws without damaging the valve.

– Process: Use methods like radiography, ultrasonic testing, and dye penetrant inspection.

7. Material Testing:

– Purpose: Confirm material integrity and composition.

– Process: Perform chemical analysis and mechanical testing like tensile and hardness tests.

Quality Control Measures

1. Documentation and Traceability:

– Maintain detailed records of all inspections and tests.

– Implement traceability for materials and components used in valve manufacturing.

2. Standard Operating Procedures (SOPs):

– Develop and adhere to SOPs for all testing and inspection processes.

– Regularly update SOPs to reflect current best practices and standards.

3. Training and Certification:

– Ensure personnel conducting tests are properly trained and certified.

– Provide continuous education to keep up with technological advancements and standards.

4. Statistical Process Control (SPC):

– Use SPC techniques to monitor and control the manufacturing process.

– Analyze data to detect and correct variations before they lead to defects.

5. Regular Audits and Reviews:

– Conduct periodic audits of testing procedures and quality control systems.

– Implement corrective actions based on audit findings to improve quality continuously.

These methods and controls help maintain high standards in shutter valve manufacturing, ensuring they meet required specifications and performance criteria.

The Work Process and how to use shutter valve

A shutter valve, also known as a gate or knife gate valve, is used in various industrial processes to control the flow of liquids or slurry. Here’s a concise guide on its work process and usage:

Work Process of a Shutter Valve

1. Operation Principle:

– The valve operates by moving a flat or curved disc (shutter) across the flow path. When the shutter is lifted, the flow path is open; when it’s lowered, the flow is blocked.

2. Opening and Closing:

– The valve can be manually operated via a handwheel or actuated electrically or pneumatically. Rotating the handwheel or activating the actuator lifts or lowers the shutter.

3. Flow Control:

– Shutter valves are primarily used for on/off control rather than flow modulation. They provide a tight seal, making them ideal for systems where full flow or complete isolation is required.

4. Material and Design:

– The valve body and shutter are typically made from robust materials like stainless steel or cast iron to withstand harsh conditions. The design ensures minimal resistance and turbulence when fully open.

How to Use a Shutter Valve

1. Installation:

– Ensure the valve is compatible with the system pressure and media type. Install the valve in the correct orientation, usually with the actuator accessible.

2. Operation:

– For manual valves, turn the handwheel to open or close. For automated systems, use the control panel to operate the valve. Always open the valve fully for maximum flow and close it completely for isolation.

3. Maintenance:

– Regularly inspect for leaks or wear, especially around seals. Lubricate moving parts if required. Clean the valve periodically to prevent build-up that can impede operation.

4. Safety:

– Ensure the system is depressurized before maintenance. Use appropriate protective gear, and follow safety protocols to avoid accidents during valve operation.

Shutter valves are reliable components in industrial systems, providing robust performance and ease of maintenance.

shutter valve Importing questions including Cost,Supplier,Sample,Certification and Market

Shutter Valve Importing Guide

1. Cost:

– Unit Price: Costs vary by material, size, and technology. Expect to pay $50-$500 per unit.

– Shipping: Consider international shipping fees, tariffs, and duties.

– Total Cost: Include import taxes and potential currency exchange rates.

2. Supplier:

– Finding Suppliers: Search on platforms like Alibaba, Global Sources, or ThomasNet. Attend trade shows or industry conferences.

– Evaluation: Assess based on reliability, production capacity, and past performance. Request company certifications and client references.

3. Sample:

– Requesting Samples: Ask suppliers for samples to evaluate quality. This might involve a nominal fee or shipping cost.

– Evaluation: Test samples for functionality, material quality, and compliance with your specifications.

4. Certification:

– Product Certification: Ensure compliance with relevant standards like ISO 9001 (Quality Management) or specific industry certifications.

– Import Certification: Check if your country requires specific certifications, such as CE marking for the EU or UL listing for North America.

5. Market:

– Demand: Research market demand in your region to gauge potential sales.

– Regulation: Understand local regulations affecting the use and installation of shutter valves.

– Competition: Analyze competitors in your target market regarding pricing, features, and distribution channels.

Summary: Importing shutter valves involves balancing cost considerations with supplier reliability and product quality. Ensure that you request and test samples, verify certifications, and understand your target market’s needs and regulatory requirements. This approach will help you make informed decisions and succeed in the market.

How to find and select check reliable shutter valve manufacturers in China

To find and select reliable shutter valve manufacturers in China, follow these steps:

1. Research Online Directories: Use reputable online platforms such as Alibaba, Made-in-China, and Global Sources. These platforms list numerous manufacturers with detailed profiles and reviews.

2. Check Certifications: Look for manufacturers with international certifications like ISO 9001, CE, and API. These certifications ensure adherence to quality management standards.

3. Review Company Profiles: Examine the company’s history, production capacity, and client portfolio. Established manufacturers with a long history and reputable clients are generally more reliable.

4. Read Reviews and Ratings: Customer reviews and ratings on the platform can provide insights into the manufacturer’s reliability and product quality. Prioritize manufacturers with consistently positive feedback.

5. Request Samples: Before making a bulk order, request product samples to assess the quality and performance of the valves. A reliable manufacturer will be willing to provide samples.

6. Visit Factories: If possible, visit the factories to inspect the production process, quality control measures, and working conditions. This helps verify the manufacturer’s capabilities and standards.

7. Evaluate Communication: Effective communication is crucial. Ensure the manufacturer is responsive and can understand your technical requirements. Reliable manufacturers will provide clear and prompt communication.

8. Check Export History: Manufacturers with extensive export experience tend to understand international standards and logistics better, reducing the risk of issues.

9. Compare Prices and Services: While competitive pricing is important, also consider after-sales service, warranty, and support. A reliable manufacturer will offer comprehensive services beyond just competitive pricing.

10. Seek Recommendations: Network with industry peers or use forums to get recommendations for reliable manufacturers.

By following these steps, you can identify and select reliable shutter valve manufacturers in China.

Background Research for shutter valve manufacturers Companies in China, use qcc.com archive.org importyeti.com

To find shutter valve manufacturers in China, you can utilize resources such as Qcc.com, ImportYeti, and Archive.org.

Qcc.com

Qcc.com is a comprehensive business database in China that provides detailed information on companies, including registration details, financial status, and more. For shutter valve manufacturers, you can perform a search on Qcc.com using relevant keywords to find a list of companies involved in this industry.

ImportYeti

ImportYeti offers a robust platform for identifying suppliers based on U.S. Customs data. By searching for “shutter valve manufacturers,” you can find detailed import histories, including shipment records and supplier lists. This can help you identify reliable manufacturers and understand their export activities. The site provides tools like the H.S. Code Explorer, which categorizes products to make your search more precise.

Archive.org

Archive.org can be used to access historical data and snapshots of websites that may have listed shutter valve manufacturers. This can be particularly useful if certain information has been removed or updated from current websites. By exploring archived versions, you can track the history and changes in company listings and industry details.

By leveraging these resources, you can gather comprehensive and reliable information on shutter valve manufacturers in China, ensuring you make well-informed decisions for your business needs.

Price Cost Research for shutter valve manufacturers Companies in China, use temu.com and 1688.com

Research on shutter valve manufacturers in China through 1688.com and Temu.com revealed various options with detailed pricing. Here are some insights:

1. 1688.com:

– Stainless Steel Ball Valves: For example, the 304 stainless steel floating ball valves are priced around ¥204.25 ($30.11) each, offered by Zhejiang Xianglong Automation Valve Technology Co., Ltd.

– Automatic Water Control Valves: Prices start at ¥1.43 ($0.21) for small-scale valves, indicating competitive pricing for bulk orders.

– Pressure Reducing Valves: These can be found at prices such as ¥231 ($34.07) from Tianjin Tangzheng Valve Co., Ltd.

2. Temu.com:

– General Pricing: The data from Temu.com was not explicitly detailed in this research, but generally, it offers a range of industrial products, often providing a platform for bulk purchases similar to 1688.com.

For businesses looking for competitive pricing and detailed product specifications, both 1688.com and Temu.com offer comprehensive options for sourcing shutter valves directly from manufacturers in China. Exploring both platforms can provide a broad view of the available market, ensuring the best prices and terms for bulk purchasing.

Shipping Cost for shutter valve import from China

Shipping costs for importing a shutter valve from China depend on several factors, including the shipping method, weight, dimensions, destination, and any additional fees. Here’s a brief overview:

Shipping Methods:

1. Air Freight:

– Cost: Typically more expensive than sea freight, but faster.

– Time: 3-7 days.

– Suitable for: Urgent shipments or lighter items.

2. Sea Freight:

– Cost: Generally cheaper than air freight.

– Time: 20-30 days.

– Suitable for: Bulk or heavy shipments where time is not critical.

Cost Breakdown:

1. Weight and Volume:

– Shipping costs are influenced by the gross weight and volume of the shipment.

– Example: For air freight, the cost could range from $5 to $10 per kilogram. For sea freight, costs can be around $1,000-$2,000 for a 20-foot container.

2. Destination:

– Shipping costs vary based on the distance between China and the destination country.

– Additional customs duties, taxes, and import fees may apply.

3. Additional Fees:

– Handling fees: Charges for loading/unloading.

– Documentation fees: Costs for shipping documents.

– Insurance: Optional but recommended to cover potential damages.

Estimated Costs:

For a single shutter valve weighing approximately 5 kg:

– Air Freight: $25 – $50 (excluding customs and handling fees).

– Sea Freight: If combined with other goods in a container, costs could be significantly lower per unit, potentially around $50 – $100 when shared.

Recommendations:

– Air Freight: For urgent needs, despite higher costs.

– Sea Freight: For bulk orders to minimize per-unit costs.

Always request a detailed quote from multiple freight forwarders to compare prices and services.

Compare China and Other shutter valve Markets: Products Quality and Price,Visible and Hidden Costs

Shutter Valve Markets: China vs. Others

#### Product Quality and Price

Chinese shutter valves often offer competitive prices due to lower manufacturing and labor costs. However, this affordability can sometimes come at the expense of quality. Chinese manufacturers may use lower-grade materials and less rigorous quality control processes compared to their Western counterparts. Conversely, shutter valves from markets like Europe, the USA, and Japan are generally more expensive but are reputed for higher quality, durability, and compliance with strict standards.

#### Visible Costs

– China: Lower upfront costs due to cheaper raw materials and labor. Prices can be significantly lower, making Chinese valves attractive for budget-conscious buyers.

– Others: Higher upfront costs due to premium materials, advanced manufacturing technologies, and stringent quality controls. These markets prioritize long-term reliability, which is reflected in the price.

#### Hidden Costs

– China: Potential hidden costs include higher maintenance and replacement rates due to inferior quality. There might be additional expenses related to import tariffs, longer lead times, and potential compliance issues with international standards.

– Others: Hidden costs can include higher initial investment and possibly longer procurement times if customization is required. However, these are often offset by lower maintenance costs and longer service life.

#### Additional Considerations

Chinese products may involve risks such as intellectual property concerns, less robust after-sales service, and potential supply chain vulnerabilities. On the other hand, Western and Japanese markets often provide robust customer support, warranties, and better alignment with international standards, which can justify the higher initial investment.

In summary, choosing between Chinese and other shutter valve markets involves balancing lower upfront costs against potential long-term expenses and quality considerations. Buyers need to evaluate their specific needs, including the criticality of the valve application, budget constraints, and acceptable risk levels.

Custom Private Labeling and Branding Opportunities with Chinese shutter valve Manufacturers

Custom private labeling and branding opportunities with Chinese shutter valve manufacturers present a range of benefits for businesses looking to enhance their market presence. China is renowned for its robust manufacturing capabilities, offering high-quality products at competitive prices. Here are key aspects to consider:

1. Cost-Effective Production: Chinese manufacturers benefit from economies of scale, allowing for lower production costs. This translates to cost savings for businesses without compromising on quality.

2. Customization Options: Manufacturers in China often provide extensive customization services, enabling businesses to create products tailored to their specific brand requirements. This includes custom designs, logos, packaging, and specifications.

3. Advanced Manufacturing Technology: Many Chinese manufacturers utilize advanced machinery and technology, ensuring precise and efficient production processes. This results in high-quality shutter valves that meet international standards.

4. Experienced Workforce: China’s manufacturing sector is supported by a skilled workforce experienced in producing a wide range of industrial products, including shutter valves. This expertise ensures reliable and consistent product quality.

5. Flexible MOQ (Minimum Order Quantity): Chinese manufacturers typically offer flexible MOQ, accommodating both large and small orders. This flexibility is advantageous for businesses at different stages of growth.

6. Regulatory Compliance: Leading Chinese manufacturers comply with international regulatory standards, including ISO, CE, and RoHS certifications. This ensures the products are safe, reliable, and suitable for global markets.

7. Efficient Supply Chain: China’s well-established logistics and supply chain networks facilitate efficient and timely delivery of products, helping businesses maintain smooth operations and meet market demands.

8. Collaborative Partnerships: Engaging with Chinese manufacturers often involves building long-term partnerships. These relationships can lead to better terms, exclusive deals, and continuous product innovation.

To capitalize on these opportunities, businesses should conduct thorough due diligence, including factory audits and quality inspections, and establish clear communication channels with the manufacturers. This approach ensures that the final products align with the brand’s vision and quality standards.

Tips for Procurement and Considerations when Purchasing shutter valve

When procuring shutter valves, several key considerations can ensure you make an informed and efficient purchase. Here are essential tips and factors to keep in mind:

1. Understand Your Requirements:

– Application: Determine the specific use-case, such as fluid type, pressure, and temperature requirements.

– Material Compatibility: Ensure the valve materials are compatible with the fluid to prevent corrosion or degradation.

2. Quality and Standards:

– Compliance: Check for compliance with industry standards such as ANSI, ISO, or API to ensure reliability and safety.

– Certification: Prefer valves from manufacturers with certifications like ISO 9001 for quality assurance.

3. Supplier Selection:

– Reputation: Choose suppliers with a proven track record and positive reviews.

– Support and Service: Opt for suppliers who offer good after-sales support, including installation guidance and maintenance services.

4. Technical Specifications:

– Size and Type: Verify the valve size and type (e.g., manual, electric, or pneumatic) matches your system requirements.

– Operating Conditions: Ensure the valve can withstand the maximum operating pressure and temperature of your system.

5. Cost Considerations:

– Budget: Balance between cost and quality. Avoid low-cost options that may compromise performance.

– Total Cost of Ownership: Consider long-term costs including maintenance, repairs, and potential downtime.

6. Durability and Maintenance:

– Longevity: Look for valves with robust construction that promise a longer lifespan.

– Ease of Maintenance: Choose designs that are easy to maintain and have readily available spare parts.

7. Lead Time and Availability:

– Stock Levels: Ensure the valve is readily available or has a reasonable lead time.

– Delivery: Confirm the supplier’s delivery capabilities to meet your project deadlines.

By thoroughly evaluating these aspects, you can make a well-informed decision, ensuring the shutter valve you purchase meets your needs and provides reliable performance.

FAQs on Sourcing and Manufacturing shutter valve in China

FAQs on Sourcing and Manufacturing Shutter Valves in China

1. Why source shutter valves from China?

China offers competitive pricing, advanced manufacturing capabilities, and a vast network of suppliers. The country’s established infrastructure and experienced workforce contribute to high-quality production at lower costs.

2. How to find reliable manufacturers?

Use online platforms like Alibaba, Made-in-China, and Global Sources to find suppliers. Verify their credentials through third-party verification services, check reviews, and request samples before making large orders.

3. What are the key factors to consider when selecting a manufacturer?

Consider the manufacturer’s experience, production capacity, quality control measures, certifications (e.g., ISO, CE), and their ability to meet your specific requirements. Assess their communication skills and responsiveness as well.

4. What quality control measures should be implemented?

Conduct factory audits, inspect raw materials, monitor production processes, and perform pre-shipment inspections. Engage third-party quality control firms for unbiased assessments to ensure product quality meets your standards.

5. How to negotiate with Chinese suppliers?

Understand the market price, build a relationship with the supplier, and be clear about your quality and delivery requirements. Negotiation should focus on price, payment terms, and delivery schedules, aiming for a win-win situation.

6. What are the common payment terms?

Common payment terms include Telegraphic Transfer (T/T), Letter of Credit (L/C), and PayPal for smaller transactions. A typical arrangement might involve a 30% deposit before production and 70% balance before shipment.

7. How to handle logistics and shipping?

Choose between air, sea, or rail freight based on your budget and urgency. Work with freight forwarders to manage shipping, customs clearance, and delivery to your location. Ensure all documentation, including the Bill of Lading, commercial invoice, and packing list, is in order.

8. What are the potential risks and how to mitigate them?

Risks include quality issues, delays, and communication barriers. Mitigate these by selecting reputable suppliers, maintaining clear communication, implementing strict quality control measures, and having contingency plans in place.

By carefully navigating these aspects, sourcing and manufacturing shutter valves in China can be a cost-effective and efficient solution for your business needs.