Top 10 lock nut types in China introduce,list main products and website if have

Here are the top 10 lock nut manufacturers in China, their main products, and their websites:

1. Ningbo Teng Qi Fasteners Co., Ltd.

– Products: Nylon Insert Lock Nuts, Deformed Thread Lock Nuts, Serrated Flange Lock Nuts.

– Website: [Teng Qi Fasteners](https://www.china-bolts.com)

2. Handan Moen Import and Export Trading Co., Ltd.

– Products: DIN985 Carbon Steel Hexagon Blue Nylon Insert Lock Nut.

– Website: [Handan Moen](https://hdmoen.en.made-in-china.com)

3. Jiaxing Goshen Hardware Co., Ltd.

– Products: Stainless Steel Hex Nut, Flange Nut, Nylon Lock Nut.

– Website: [Goshen Hardware](https://goshenhardware.en.made-in-china.com)

4. Yangzhou XIYI Fasteners Co., Ltd.

– Products: Nylon Insert Lock Nut, Stover Lock Nut, K-Lock Nut, Reverse Lock Nut, Flange Lock Nut.

– Website: [XIYI Fasteners](https://china-fasteners.com)

5. Shenzhen Yijin Hardware Co., Ltd.

– Products: Threaded Fasteners, Rivets, Assembly Parts, Cold Forming Parts.

– Website: [Yijin Hardware](https://www.yijinsolution.com)

6. Shanghai Jianxin Hardware Co., Ltd.

– Products: High-precision Fasteners, Custom Fasteners.

– Website: [Jianxin Hardware](https://www.jianxinhardware.com)

7. Shanghai Tianbao Fastener Co., Ltd.

– Products: Pressure Riveting Fasteners, Non-standard Parts.

– Website: [Tianbao Fasteners](https://www.tianbaofastener.com)

8. Jiaxing Qimu Trading Co., Ltd.

– Products: High-Strength Bolts, Hexagonal Bolts, Nuts, Washers.

– Website: [Qimu Trading](https://www.qimutrading.com)

9. Shanghai Jingyang Fastener Co., Ltd.

– Products: High-Strength Fasteners, Hexagon Bolts, Flange Bolts.

– Website: [Jingyang Fastener](https://www.jingyangfastener.com)

10. Ningbo Weiye Fastener Co., Ltd.

– Products: High-Strength Nuts, Nylon Insert Lock Nuts, Metal Insert Lock Nuts.

– Website: [Weiye Fastener](https://www.wyfastener.com)

These companies are noted for their variety in lock nut types, including nylon insert, serrated flange, and high-strength lock nuts, catering to industries requiring robust fastening solutions. For more details, you can visit their respective websites.

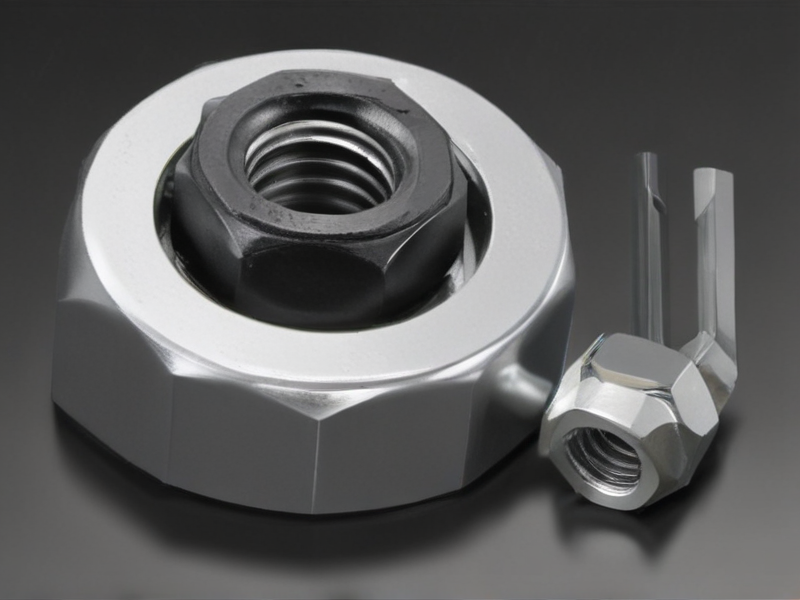

Types of lock nut types

Lock nuts are designed to prevent the loosening of fasteners due to vibration or torque. Here are several common types:

1. Nylon Insert Lock Nuts (Nyloc Nuts):

– Feature a nylon collar that grips the bolt thread.

– Suitable for applications where the bolt may be removed occasionally.

2. Jam Nuts:

– Thin nuts used in conjunction with a standard nut.

– Tightened against the main nut to prevent loosening.

3. All-Metal Lock Nuts:

– Entirely made of metal, often with deformed threads.

– Suitable for high-temperature environments where nylon might melt.

4. Serrated Flange Lock Nuts:

– Have a serrated flange that grips the mating surface.

– Provide increased resistance to loosening through vibration.

5. K-Lock Nuts (Keplock Nuts):

– Feature a free-spinning, captive lock washer.

– The washer creates friction, preventing the nut from loosening.

6. Prevailing Torque Lock Nuts:

– Have deformed threads or a non-circular shape.

– Maintain a constant pressure against the bolt thread.

7. Castle Nuts (Castellated Nuts):

– Slotted nut used with a cotter pin or wire.

– Commonly used in applications requiring frequent adjustment.

8. Stover Lock Nuts:

– Have a conical top that creates interference fit on bolt threads.

– Provide a vibration-resistant locking action.

9. Tapered Lock Nuts:

– Use a conical design to create a secure fit.

– Ideal for high-vibration applications.

Each type of lock nut is chosen based on the specific requirements of the application, such as temperature, need for reusability, and the extent of vibration or movement in the assembly.

Pros and Cons of Using lock nut types

Pros and Cons of Using Different Lock Nut Types

1. Nylon Insert Lock Nuts

– Pros:

– Vibration Resistance: The nylon insert provides strong resistance to loosening from vibrations.

– Reusable: Can be used multiple times, though with some loss of effectiveness.

– Cost-Effective: Generally inexpensive and readily available.

– Cons:

– Temperature Sensitivity: Not suitable for high-temperature applications as the nylon can melt.

– Limited Load Capacity: Not ideal for heavy load applications.

2. Metal Lock Nuts

– Pros:

– High Strength: Suitable for high load and high-stress environments.

– Temperature Resistant: Can withstand high temperatures without losing effectiveness.

– Durability: Very durable and long-lasting.

– Cons:

– Cost: More expensive compared to nylon insert lock nuts.

– Corrosion: May require additional coatings or materials to prevent rusting.

3. Serrated Flange Lock Nuts

– Pros:

– Excellent Vibration Resistance: Serrations provide strong grip, preventing loosening.

– No Need for Washers: The flange distributes pressure, reducing the need for washers.

– Easy to Install: Simple and quick installation process.

– Cons:

– Surface Damage: Serrations can damage the mating surface.

– One-Time Use: Typically, not reusable as serrations wear out.

4. Prevailing Torque Lock Nuts

– Pros:

– Consistent Performance: Maintains a consistent torque level.

– Vibration Resistance: Effective in high-vibration environments.

– Temperature Resistant: Suitable for various temperatures.

– Cons:

– Installation Difficulty: Can be harder to install due to the high prevailing torque.

– Wear and Tear: Repeated use can degrade their effectiveness.

5. Jam Nuts

– Pros:

– Simple Design: Easy to use and install.

– Cost-Effective: Inexpensive option for locking applications.

– Cons:

– Less Effective for Vibration: Not as effective in preventing loosening from vibrations.

– Requires Two Nuts: Needs an additional standard nut for effectiveness.

Conclusion: The choice of lock nut depends on specific application requirements, including load capacity, environmental conditions, and budget. Each type has its unique advantages and limitations that should be carefully considered.

lock nut types Reference Specifications (varies for different product)

Reference Specifications for Different Types of Lock Nuts

Lock nuts are essential components used to secure bolted joints and prevent them from loosening under vibrations or torque. Different types of lock nuts offer unique features and specifications based on their design and application. Below is an overview of common lock nut types and their reference specifications:

#### 1. Nylon Insert Lock Nuts (Nylock Nuts)

– Material: Steel, stainless steel, brass

– Finish: Zinc plated, plain, black oxide

– Temperature Range: Up to 250°F (120°C)

– Thread Size: Varies, typically from #2-56 to 1-1/2″-12

– Features: Nylon collar insert grips the threads to resist loosening

– Applications: Automotive, aerospace, machinery

#### 2. All-Metal Lock Nuts

– Material: Steel, stainless steel, brass

– Finish: Zinc plated, plain, black oxide

– Temperature Range: Higher than nylon inserts, up to 1000°F (538°C)

– Thread Size: Varies, typically from #2-56 to 1-1/2″-12

– Features: Deformed threads or prevailing torque for locking

– Applications: High-temperature environments, heavy machinery

#### 3. K-Lock Nuts (Keps Nuts)

– Material: Steel, stainless steel

– Finish: Zinc plated, plain

– Temperature Range: Standard range based on material

– Thread Size: Varies, typically from #2-56 to 1″-8

– Features: Integrated free-spinning washer with serrations

– Applications: Electronics, automotive, general fastening

#### 4. Castle Nuts (Slotted Nuts)

– Material: Steel, stainless steel, brass

– Finish: Zinc plated, plain

– Thread Size: Varies, typically from 1/4″-20 to 1″-14

– Features: Slots for cotter pin insertion

– Applications: Aircraft, automotive, machinery

#### 5. Hex Flange Lock Nuts

– Material: Steel, stainless steel

– Finish: Zinc plated, plain, black oxide

– Thread Size: Varies, typically from #4-40 to 1″-8

– Features: Integrated washer for even load distribution

– Applications: Automotive, construction, manufacturing

#### 6. Flex-Top Lock Nuts

– Material: Steel, stainless steel

– Finish: Zinc plated, plain

– Thread Size: Varies, typically from #6-32 to 1″-8

– Features: Distorted thread for prevailing torque

– Applications: High-vibration environments

General Considerations

– Torque Specifications: Vary based on nut size, material, and application. Always refer to manufacturer recommendations.

– Standards Compliance: Many lock nuts comply with standards such as ANSI, ASME, DIN, and ISO.

Selecting the appropriate lock nut depends on the specific requirements of the application, including environmental conditions, load capacity, and material compatibility. Always consult technical datasheets and manufacturer guidelines for precise specifications.

Applications of lock nut types

Lock nuts are essential in various industries for securing bolted connections. Here are some common types and their applications:

1. Nylon Insert Lock Nuts (Nyloc Nuts):

– Applications: Used in automotive, aerospace, and machinery.

– Features: A nylon insert that increases friction on the bolt thread, preventing loosening.

2. Jam Nuts:

– Applications: Often used in pairs with another nut, common in automotive and agricultural equipment.

– Features: Thin nuts that are tightened against a standard nut to prevent loosening.

3. Prevailing Torque Lock Nuts:

– Applications: Suitable for high-vibration environments, such as engines and heavy machinery.

– Features: Deformed threads create friction and resistance to loosening without the need for extra parts.

4. Keps (K-Lock) Nuts:

– Applications: Electronics and electrical assemblies.

– Features: Integrated free-spinning washer for ease of assembly and improved grip.

5. Flange Lock Nuts:

– Applications: Automotive, especially in suspension systems.

– Features: Built-in washer (flange) that distributes pressure and reduces damage to the surfaces being fastened.

6. Serrated Flange Lock Nuts:

– Applications: Heavy-duty machinery and construction.

– Features: Serrations on the flange that bite into the surface for a more secure hold.

7. Castle Nuts:

– Applications: Used with a cotter pin for secure fastening in automotive and aerospace.

– Features: Slots that align with a hole in the bolt for insertion of a cotter pin, preventing rotation.

8. Flex-Top Lock Nuts:

– Applications: Industrial machinery and railways.

– Features: Top portion flexes to create a secure, vibration-resistant lock.

9. Locking Wheel Nuts:

– Applications: Automotive wheels.

– Features: Special designs that require a unique key to remove, providing theft resistance.

Each type of lock nut provides specific benefits tailored to its application, enhancing the security and reliability of mechanical connections.

Material of lock nut types

Lock nuts are specialized nuts designed to prevent loosening due to vibrations or torque. Various types of lock nuts are made from different materials, each chosen based on specific application requirements. Here are common types and their materials:

1. Nylon Insert Lock Nuts:

– Material: Usually made from stainless steel, carbon steel, or alloy steel with a nylon insert.

– Properties: The nylon insert provides friction against the bolt threads to prevent loosening without damaging the threads.

2. All-Metal Lock Nuts:

– Material: Typically made from stainless steel, carbon steel, alloy steel, or brass.

– Properties: These nuts rely on their metal deformation and thread friction to lock in place. Examples include prevailing torque lock nuts and serrated flange lock nuts.

3. Keps Lock Nuts (K-Lock Nuts):

– Material: Often made from stainless steel or carbon steel.

– Properties: Feature an attached, free-spinning washer that enhances locking by increasing friction.

4. Castle Nuts:

– Material: Commonly made from carbon steel or stainless steel.

– Properties: Used with a cotter pin or wire to lock the nut in place, providing a secure fit for critical applications.

5. Flex-Top Lock Nuts:

– Material: Manufactured from high-strength steel or stainless steel.

– Properties: These nuts have a slotted top that deforms elastically to grip the bolt threads.

6. Torque-Lock Nuts:

– Material: Made from alloy steel, stainless steel, or carbon steel.

– Properties: These have a conical shape that deforms to lock the nut in place under torque.

7. Flange Lock Nuts:

– Material: Commonly stainless steel, carbon steel, or alloy steel.

– Properties: Have a wide flange that distributes pressure and increases friction to prevent loosening.

The choice of material depends on factors such as strength requirements, environmental conditions (corrosion resistance), and the specific application’s mechanical stress.

Quality Testing Methods for lock nut types and how to control the quality

Quality testing for lock nuts involves several methods to ensure their reliability and performance. Here are the primary testing methods and quality control measures:

1. Dimensional Inspection:

– Method: Use calipers, micrometers, and thread gauges to verify dimensions and thread accuracy.

– Control: Implement standard operating procedures (SOPs) for measurement and maintain calibration of measuring instruments.

2. Material Testing:

– Method: Conduct chemical composition analysis using spectrometers and mechanical testing (tensile, hardness, impact) to ensure material meets specifications.

– Control: Source materials from certified suppliers and perform regular audits.

3. Surface Coating Inspection:

– Method: Use coating thickness gauges and visual inspection for uniformity and adherence.

– Control: Standardize coating processes and perform batch testing.

4. Torque Testing:

– Method: Use torque wrenches to apply and measure the torque required to lock and unlock the nut.

– Control: Set torque standards based on application requirements and conduct routine checks.

5. Vibration Testing:

– Method: Employ vibration testing machines to simulate operational conditions and evaluate lock nut performance.

– Control: Define vibration test cycles and criteria for acceptable performance.

6. Salt Spray Test:

– Method: Expose lock nuts to salt spray (fog) to assess corrosion resistance.

– Control: Follow ASTM B117 standards for test duration and evaluation.

7. Fatigue Testing:

– Method: Subject lock nuts to cyclic loading to test endurance.

– Control: Establish fatigue limits based on application-specific load conditions.

8. Lot Traceability:

– Method: Maintain detailed records of production batches, including raw material certificates and test results.

– Control: Implement a robust traceability system to track and recall defective batches if needed.

Regular audits, statistical process control (SPC), and adherence to international standards (e.g., ISO, DIN) ensure ongoing quality. By integrating these testing methods and controls, manufacturers can consistently produce high-quality lock nuts.

The Work Process and how to use lock nut types

Work Process of Using Lock Nut Types

1. Selection:

– Identify Application Needs: Determine the load, vibration, and environmental conditions.

– Choose Lock Nut Type: Select the appropriate lock nut based on application needs. Common types include nylon insert lock nuts, all-metal lock nuts, and serrated flange lock nuts.

2. Preparation:

– Inspect Threads: Ensure that both the bolt and nut threads are clean and free from damage.

– Gather Tools: Assemble necessary tools, such as wrenches, torque wrenches, and thread lockers (if needed).

3. Installation:

– Position Nut: Place the lock nut onto the bolt or threaded rod.

– Hand Tighten: Initially hand tighten the lock nut to ensure proper thread engagement.

– Use Appropriate Tool: Use a wrench or torque wrench to tighten the nut to the specified torque value.

– Nylon Insert Lock Nuts: These have a nylon ring that provides friction. Do not overtighten to avoid damaging the nylon insert.

– All-Metal Lock Nuts: Made entirely of metal and rely on deformed threads. Ensure correct alignment and apply sufficient torque.

– Serrated Flange Lock Nuts: These have serrations on the flange that dig into the material surface. Avoid over-torquing to prevent damage to the flange or the surface.

4. Verification:

– Check Tightness: Verify the tightness using a torque wrench to ensure the nut is properly secured.

– Inspection: Regularly inspect the lock nut during maintenance to ensure it remains tight and undamaged.

5. Maintenance:

– Routine Checks: Periodically check the tightness, especially in applications subject to vibration.

– Replace If Necessary: Replace lock nuts if they show signs of wear, damage, or if the nylon insert loses its effectiveness.

By following these steps, lock nuts can be effectively used to secure assemblies, ensuring reliability and safety in various applications.

lock nut types Importing questions including Cost,Supplier,Sample,Certification and Market

When considering the import of lock nuts, it’s crucial to address several key questions to ensure a smooth and efficient process. These include cost, supplier reliability, sample availability, certification requirements, and market considerations.

1. Cost:

– What is the unit cost of each type of lock nut?

– Are there bulk purchase discounts available?

– What are the shipping and handling costs to your location?

– Are there any additional import duties or taxes?

2. Supplier:

– Who are the leading suppliers of lock nuts in the market?

– What is the supplier’s reputation and reliability?

– Can the supplier provide references or case studies?

– What are the payment terms offered by the supplier?

3. Sample:

– Is it possible to obtain samples before placing a bulk order?

– What is the cost of obtaining these samples?

– How long does it take to receive the samples?

– Are there any quality assurance processes in place for sample testing?

4. Certification:

– What certifications are required for importing lock nuts into your country?

– Does the supplier have the necessary certifications (e.g., ISO, CE)?

– Can the supplier provide documentation proving compliance with certification standards?

– Are there any additional testing or certification requirements after import?

5. Market:

– What is the current demand for lock nuts in your target market?

– Who are the main competitors, and what are their price points?

– What are the preferred types and specifications of lock nuts in the market?

– What are the potential barriers to entry, such as regulatory requirements or existing supplier contracts?

Addressing these questions will help in making informed decisions, ensuring quality and compliance, and achieving a successful import process.

How to find and select check reliable lock nut types manufacturers in China

To find and select reliable lock nut types manufacturers in China, follow these steps:

1. Research and Identify Potential Manufacturers:

– Online Marketplaces: Use platforms like Alibaba, Made-in-China, and Global Sources to search for lock nut manufacturers.

– Industry Directories: Check directories such as China.cn, or 1688.com (Chinese version of Alibaba).

– Trade Shows: Attend or browse online catalogs from trade shows like the Canton Fair and China International Hardware Show.

2. Evaluate Manufacturers:

– Reputation: Look for manufacturers with high ratings and positive reviews. Check for any awards or certifications.

– Experience: Prefer manufacturers with several years of experience in producing lock nuts.

– Certifications: Ensure the manufacturers have relevant certifications such as ISO 9001, CE, or others indicating quality compliance.

3. Contact and Inquire:

– Request Information: Ask for catalogs, product specifications, and company profiles.

– Certifications and Compliance: Confirm the presence of required certifications and adherence to international standards.

– References: Request references from previous customers, preferably from your country or industry.

4. Assess Production Capability and Quality Control:

– Site Visits: If possible, visit the factories to assess their production capabilities and quality control processes.

– Samples: Request samples to evaluate the quality of the products firsthand.

5. Negotiate Terms:

– Pricing and MOQ: Discuss pricing, minimum order quantities (MOQ), and payment terms.

– Lead Time: Confirm production and delivery lead times to ensure they meet your requirements.

6. Verify and Finalize:

– Background Check: Perform a background check to verify the company’s legitimacy and track record.

– Trial Order: Place a trial order to test the manufacturer’s reliability before committing to larger orders.

By following these steps, you can identify and select reliable lock nut types manufacturers in China.

Background Research for lock nut types manufacturers Companies in China, use qcc.com archive.org importyeti.com

Several companies in China specialize in manufacturing lock nuts, each with a distinct focus and market reach:

1. Suzhou Victory Precision Manufacturing Technology Co., Ltd.: Located in Suzhou, Jiangsu Province, this company is a large-scale manufacturer engaged in producing various metal products, including precision lock nuts. With a significant workforce and substantial revenue, Victory Precision is well-established in the industry.

2. Qijing Machinery Co., Ltd.: Based in Ningbo, Zhejiang Province, Qijing Machinery specializes in producing mechanical components, including high-quality lock nuts. The company has evolved from a small tool manufacturer to a significant player in the machinery industry.

3. Kunshan Kensetsu Buhin Manufacturing Co., Ltd.: Situated in Kunshan, Jiangsu Province, this company focuses on manufacturing a wide range of fasteners, including lock nuts, primarily serving the automotive and machinery sectors. Known for their precision and reliability, their products are well-regarded in both domestic and international markets.

These manufacturers are notable for their advanced production capabilities, extensive market presence, and commitment to quality, making them key players in the lock nut manufacturing industry in China. For more detailed company profiles and specific product information, refer to their respective listings on [QCC.com](https://www.qcc.com).

Price Cost Research for lock nut types manufacturers Companies in China, use temu.com and 1688.com

When researching lock nut manufacturers in China, platforms like Temu.com and 1688.com provide a variety of options. Here are some insights from both sites:

Temu.com

1. Product Range: Temu.com offers a wide array of lock nuts, including standard, self-locking, and specialized variants for various industrial applications. Notable categories include mechanic tools and auto parts where lock nuts are prevalent.

2. Pricing: Prices vary significantly depending on the type and specifications of the lock nuts. Basic lock nuts start from around $0.30 to $1.50 per piece for standard sizes and materials.

3. Manufacturers: Temu lists various manufacturers, providing options for both bulk and individual purchases, catering to different industrial needs.

1688.com

1. Product Range: 1688.com features an extensive selection of lock nuts, including precision lock nuts, round lock nuts, and self-locking varieties. The platform hosts suppliers that specialize in high-precision and heavy-duty lock nuts suitable for machinery and automotive industries.

2. Pricing: Prices on 1688.com range from ¥0.43 for basic models to ¥165.0 for high-precision and specialized lock nuts, such as those used in CNC machines and heavy machinery. For example, a standard round lock nut (JSAUTO brand) costs around ¥15.2 per piece.

3. Manufacturers: Suppliers like Guangzhou New Nord Transmission Parts Co., Ltd. and Suzhou Ouyin Precision Mechanical and Electrical Co., Ltd. are prominent on the platform. These suppliers offer detailed specifications and bulk purchasing options, with some providing additional services like 7-day replacements and custom manufacturing.

Both platforms provide robust search functionalities and supplier ratings to help identify the best options based on price, quality, and supplier reliability.

Shipping Cost for lock nut types import from China

The shipping cost for importing lock nut types from China depends on several factors: the mode of transportation, the weight and volume of the shipment, the distance to the destination, and any additional services required (e.g., insurance, customs clearance).

1. Modes of Transportation:

– Air Freight: Faster but more expensive, suitable for urgent or high-value items. Costs can range from $4 to $8 per kilogram.

– Sea Freight: Economical for large volumes, though slower. Costs can range from $1,000 to $4,000 for a 20-foot container, depending on the route and shipping line.

– Courier Services (e.g., DHL, FedEx): Suitable for small, urgent shipments. Costs are typically higher than regular air freight, often between $10 to $20 per kilogram.

2. Weight and Volume:

– Less than Container Load (LCL): If your shipment doesn’t fill a container, you pay for space used. LCL rates can be around $30 to $40 per cubic meter.

– Full Container Load (FCL): A flat rate for the whole container, advantageous for large shipments. A 20-foot container typically holds 28 cubic meters.

3. Additional Costs:

– Customs Duties and Taxes: Varies by country; typically calculated as a percentage of the shipment value.

– Handling Fees: Charges for loading/unloading, warehousing, and documentation can add $50 to $200.

– Insurance: Recommended for high-value shipments; typically 0.5% to 1% of the cargo value.

4. Sample Calculation:

– Air Freight Example: 500 kg of lock nuts from Shanghai to Los Angeles at $6/kg = $3,000.

– Sea Freight Example: 10 cubic meters LCL shipment from Shenzhen to Hamburg at $35/cubic meter = $350.

5. Conclusion:

– For Small, Urgent Orders: Air freight or courier services.

– For Large, Non-Urgent Orders: Sea freight (FCL or LCL).

Request quotes from multiple shipping companies for the best rates and services.

Compare China and Other lock nut types Markets: Products Quality and Price,Visible and Hidden Costs

China vs. Other Markets for Lock Nuts: A Comparison

#### Product Quality and Price

China:

– Quality: Chinese manufacturers offer a broad range of lock nuts, from low to high quality. Advanced technology and rigorous quality control in top-tier factories ensure competitive standards.

– Price: Generally lower due to economies of scale and lower labor costs. This makes China a preferred supplier for cost-sensitive buyers.

Other Markets (e.g., USA, Germany, Japan):

– Quality: Typically higher and more consistent due to stringent regulations and advanced manufacturing techniques.

– Price: Significantly higher, reflecting superior materials, manufacturing processes, and labor costs.

#### Visible and Hidden Costs

Visible Costs:

– China: Lower upfront costs for lock nuts, making it attractive for large volume purchases.

– Other Markets: Higher upfront costs due to superior quality and stringent manufacturing standards.

Hidden Costs:

– China:

– Quality Assurance: Potential additional costs for third-party inspections and quality assurance to ensure product standards.

– Logistics: Longer shipping times and higher freight costs can impact overall cost-effectiveness.

– Customs and Duties: Potential tariffs and import duties can add to the total cost.

– Warranty and Returns: Potentially higher rates of returns or replacements due to variable quality.

– Other Markets:

– Reliability: Lower hidden costs due to reliable quality and lower defect rates.

– Compliance: Fewer issues with regulatory compliance, reducing the risk of additional costs.

– Lead Time: Shorter lead times can reduce inventory holding costs and improve supply chain efficiency.

– After-Sales Service: Better support and warranty services, reducing long-term maintenance costs.

In summary, while Chinese lock nuts are attractive for their low upfront costs, buyers must consider potential hidden costs associated with quality assurance, logistics, and compliance. Other markets, though more expensive, often provide higher quality and reliability, potentially resulting in lower total costs over time.

Custom Private Labeling and Branding Opportunities with Chinese lock nut types Manufacturers

Collaborating with Chinese manufacturers for custom private labeling and branding of lock nuts offers substantial opportunities for businesses. Chinese manufacturers are renowned for their cost-effective production, vast manufacturing capabilities, and flexibility in customization, making them ideal partners for private labeling initiatives.

Advantages of Custom Private Labeling with Chinese Manufacturers

1. Cost Efficiency: Chinese manufacturers offer competitive pricing due to lower production costs, which allows businesses to achieve higher profit margins.

2. Scalability: With large-scale production capabilities, Chinese manufacturers can handle small to large orders, making it easy to scale as demand grows.

3. Customization: Chinese manufacturers provide extensive customization options, including different materials, sizes, coatings, and packaging, to meet specific branding and quality requirements.

4. Quick Turnaround: Efficient production processes and advanced logistics networks in China facilitate faster lead times, ensuring timely delivery of products.

5. Quality Control: Many Chinese manufacturers adhere to international quality standards and offer rigorous quality control measures to ensure product consistency and reliability.

Key Steps in the Process

1. Manufacturer Selection: Choose a reputable manufacturer with experience in producing lock nuts. Verify their certifications, quality control processes, and previous client feedback.

2. Design and Specification: Work closely with the manufacturer to finalize the design, material specifications, and any unique features of the lock nuts.

3. Prototyping: Request samples or prototypes to ensure the product meets the desired standards and specifications before full-scale production.

4. Branding and Packaging: Collaborate on customized branding and packaging solutions that reflect your brand’s identity, including logos, colors, and packaging materials.

5. Production and Quality Assurance: Oversee the production process and implement stringent quality control checks to maintain product quality.

6. Logistics and Distribution: Plan and execute the logistics for shipping and distribution, ensuring that products reach the market efficiently and on time.

Conclusion

Engaging with Chinese manufacturers for custom private labeling and branding of lock nuts is a strategic move that can enhance product offerings, strengthen brand identity, and improve market competitiveness. By leveraging China’s manufacturing expertise, businesses can achieve high-quality, customized products at competitive prices.

Tips for Procurement and Considerations when Purchasing lock nut types

When procuring lock nuts, consider the following tips and factors to ensure optimal performance and cost-efficiency:

1. Understand Application Requirements: Different applications require different lock nut types. Consider the environment (e.g., vibration, temperature), load conditions, and material compatibility.

2. Material Selection: Choose materials based on strength, corrosion resistance, and weight. Common materials include stainless steel, nylon, and brass. For high-stress applications, grade 8 or higher steel nuts might be necessary.

3. Locking Mechanism: There are various types of lock nuts, such as nylon insert nuts, all-metal lock nuts, and prevailing torque nuts. Nylon insert nuts are suitable for moderate vibration environments, while all-metal lock nuts are better for high-temperature applications.

4. Thread Fit and Size: Ensure the thread size and pitch match the mating bolt. Proper thread fit is crucial to maintain the locking capability and prevent loosening.

5. Quality and Standards: Source from reputable suppliers that adhere to industry standards like ISO, DIN, or ANSI. This ensures consistent quality and performance.

6. Cost vs. Performance: Balance the cost with performance needs. High-quality lock nuts may have a higher upfront cost but can save money in the long run by reducing maintenance and replacements.

7. Bulk Purchasing: Consider bulk purchasing for cost savings but ensure the storage conditions prevent degradation, especially for nylon-based nuts.

8. Supplier Reliability: Choose suppliers with a good track record for timely delivery and product consistency. Check reviews and ask for certifications or compliance documents.

9. Testing and Certification: If possible, test the lock nuts in a controlled environment simulating actual conditions. Request material certifications and quality test results from suppliers.

10. Environmental Considerations: For critical or safety-related applications, consider the environmental impact and choose lock nuts that meet environmental regulations and sustainability standards.

By considering these factors, procurement professionals can ensure they select the most appropriate and cost-effective lock nuts for their specific needs.

FAQs on Sourcing and Manufacturing lock nut types in China

FAQs on Sourcing and Manufacturing Lock Nut Types in China

1. What are the types of lock nuts commonly manufactured in China?

Chinese manufacturers produce a wide variety of lock nuts, including nylon insert lock nuts, all-metal lock nuts, flange lock nuts, serrated flange lock nuts, and prevailing torque lock nuts. Each type serves different applications and industries.

2. How do I find a reliable lock nut manufacturer in China?

Utilize platforms like Alibaba, Global Sources, and Made-in-China. Check manufacturer credentials, request product samples, verify certifications (ISO, RoHS), and read reviews or get referrals from industry contacts.

3. What is the typical production capacity of Chinese lock nut manufacturers?

Production capacities vary by manufacturer but typically range from millions to tens of millions of units per month. High-capacity manufacturers can handle large orders efficiently.

4. What are the common materials used for lock nuts in China?

Manufacturers commonly use stainless steel, carbon steel, alloy steel, and sometimes brass. The choice of material depends on the required strength, corrosion resistance, and specific application.

5. Can Chinese manufacturers produce custom lock nuts?

Yes, many manufacturers offer customization services. Provide detailed specifications, including dimensions, materials, and any specific standards or certifications needed.

6. What are the quality control measures in place for lock nut manufacturing in China?

Reputable manufacturers follow stringent quality control measures, including raw material inspection, in-process quality checks, and final product testing. Many adhere to international standards like ISO 9001.

7. What is the lead time for bulk orders?

Lead times vary but typically range from 30 to 60 days, depending on order size and complexity. Ensure clear communication with the manufacturer to confirm timelines.

8. What are the payment terms for sourcing lock nuts from China?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal for smaller orders. Initial orders might require a 30-50% deposit, with the balance paid before shipment.

9. How is shipping and logistics handled?

Manufacturers usually handle shipping through FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms. Collaborate with a reliable freight forwarder for efficient logistics and customs clearance.

10. Are there any import regulations to be aware of?

Check your country’s import regulations regarding product standards, certifications, and any tariffs or duties applicable to lock nuts. Compliance ensures a smooth import process.