Top 10 chain and binder in China introduce,list main products and website if have

Here are the top 10 chain and binder manufacturers in China, along with their main products and websites:

1. Qingdao Sincere Metal Product Co., Ltd.

– Main Products: Chain load binders, ratchet load binders, forged steel transport chains.

– Website: [riggingcn.en.made-in-china.com](https://riggingcn.en.made-in-china.com)

2. Chongqing Deso Lifting Co., Ltd.

– Main Products: Chains, chain blocks, lever blocks, manual hoists.

– Website: [desolifting.en.made-in-china.com](https://desolifting.en.made-in-china.com)

3. Weifang First Rigging Co., Ltd.

– Main Products: Chains, master links, rigging, shackles, hooks.

– Website: [rigging.en.made-in-china.com](https://rigging.en.made-in-china.com)

4. Qingdao Haito Rigging Hardware Co., Ltd.

– Main Products: Chain ratchet load binders, lifting chains, hooks.

– Website: [qdhaitorigging.en.made-in-china.com](https://qdhaitorigging.en.made-in-china.com)

5. Zhenjiang Huangxu Anchor Chain Co., Ltd.

– Main Products: Transmission chains, drag chains, conveyor chains.

– Website: [huangxumaolian.en.made-in-china.com](https://huangxumaolian.en.made-in-china.com)

6. Qingdao Yongxin Rigging Co., Ltd.

– Main Products: Ratchet load binders, lever load binders, transport chains.

– Website: [yongxin-rigging.en.made-in-china.com](https://yongxin-rigging.en.made-in-china.com)

7. Taizhou Minghe Technology Co., Ltd.

– Main Products: Steel load binders, lifting chains, forged hooks.

– Website: [mhhoist.en.made-in-china.com](https://mhhoist.en.made-in-china.com)

8. ZHEZHONG Lifting Co., Ltd.

– Main Products: Lever chain binders, ratchet straps, lifting chains.

– Website: [z2-lifting.com](https://www.z2-lifting.com)

9. Hebei Juying Hoisting Machinery Co., Ltd.

– Main Products: Galvanized lifting load binders, alloy chains.

– Website: [juyingqz.en.made-in-china.com](https://juyingqz.en.made-in-china.com)

10. Qingdao Seger Industrial Co., Ltd.

– Main Products: Forged ratchet load binders, carbon steel chains.

– Website: [cnseger.en.made-in-china.com](https://cnseger.en.made-in-china.com)

These companies are renowned for their high-quality products used in securing loads for transport, offering various types of chain and binder solutions. For further details, you can visit their websites.

Types of chain and binder

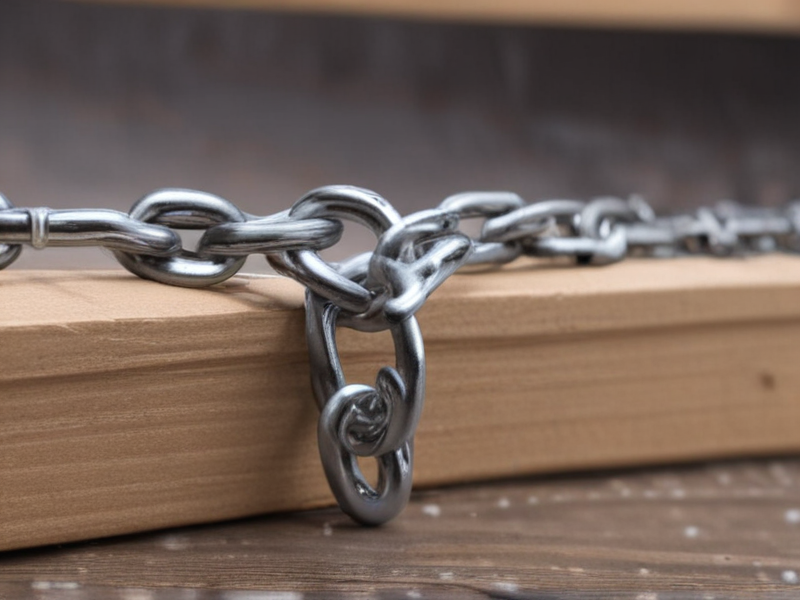

Types of Chains

1. Link Chains:

– Welded Link Chains: Each link is permanently joined, commonly used for lifting and securing loads.

– Twist Link Chains: Links are twisted 90 degrees, offering flexibility, used in playground equipment.

– Stud Link Chains: Reinforced with a stud across the center, typically used in marine applications for anchors.

2. Roller Chains:

– Single-Strand Roller Chains: Used in simple machinery for power transmission.

– Double-Strand Roller Chains: Provide greater strength for heavy-duty applications.

– Triple-Strand Roller Chains: Used in extremely demanding environments for robust power transmission.

3. Detachable Chains:

– Ladder Chains: Easily assembled and disassembled, used in agricultural machinery.

– Hollow Pin Chains: Features hollow pins for attachments, common in conveyors.

Types of Binders

1. Load Binders:

– Ratchet Binders: Use a ratcheting mechanism to tighten the chain, offering controlled tensioning, ideal for heavy-duty applications.

– Lever Binders: Operated by a lever to tighten the chain, quicker to use but requires more physical effort and caution.

2. Wire Rope Binders:

– Ratchet Wire Rope Binders: Use wire ropes instead of chains, suitable for securing irregular loads.

– Lever Wire Rope Binders: Similar to lever binders but with wire rope, offering flexibility in securing loads.

3. Strap Binders:

– Cam Buckle Straps: Use a cam buckle to tighten the strap, commonly used for lighter loads.

– Ratchet Straps: Use a ratcheting mechanism to secure the load, ideal for heavy or irregularly shaped loads.

4. Twist Lock Binders:

– Container Twist Locks: Used to secure shipping containers, locking them to the transport vehicle or each other.

These chains and binders are essential for various industrial, agricultural, and transportation applications, ensuring safety and efficiency in securing and moving loads.

Pros and Cons of Using chain and binder

Chain and Binder: Pros and Cons

Pros:

1. Strength and Security:

– Chains are typically made of metal, providing high tensile strength. This ensures that items secured with a chain and binder system are less likely to break free, making them ideal for heavy loads and high-security needs.

2. Versatility:

– Chain and binder systems can be used in a variety of applications, from securing cargo on flatbed trucks to securing equipment and machinery. This versatility makes them a popular choice in many industries.

3. Durability:

– Chains and binders are highly durable and can withstand harsh environmental conditions, such as extreme temperatures, moisture, and abrasion, which makes them suitable for outdoor and industrial use.

4. Adjustability:

– The binder allows for easy adjustment of tension in the chain, providing a customizable level of security and ensuring that the load is held firmly in place.

Cons:

1. Weight:

– Chains and binders are heavy, which can add significant weight to the load. This can be a disadvantage in applications where weight is a critical factor, such as in transportation where fuel efficiency is important.

2. Cost:

– High-quality chains and binders can be expensive compared to other securing methods, such as straps. This initial cost can be a barrier for small businesses or infrequent users.

3. Complexity and Time:

– Using a chain and binder system can be more complex and time-consuming compared to simpler methods like ratchet straps. Proper tensioning and securing require skill and practice, which can increase loading and unloading times.

4. Potential for Injury:

– Mishandling chains and binders can pose a risk of injury. The heavy weight and the tension required can lead to strains, pinches, or more severe injuries if not used correctly.

In summary, while chains and binders offer strong, durable, and versatile securing options, they also come with drawbacks such as weight, cost, complexity, and potential safety risks. Their use is often dictated by the specific needs and constraints of the task at hand.

chain and binder Reference Specifications (varies for different product)

Chain Specifications

1. Material: Chains are commonly made from high-grade steel, stainless steel, or alloy steel to ensure strength and durability.

2. Size: Chain sizes vary based on their application and are specified by their diameter (e.g., 1/4″, 5/16″, 3/8″).

3. Grade: Common grades include Grade 30 (Proof Coil), Grade 43 (High Test), Grade 70 (Transport), Grade 80 (Alloy), and Grade 100. Each grade indicates the tensile strength and load capacity.

4. Breaking Strength: The maximum force a chain can withstand before breaking, usually measured in pounds or kilograms.

5. Working Load Limit (WLL): The maximum weight that the chain can safely hold during regular use. This is typically 1/3 of the chain’s breaking strength.

6. Length: Chains are available in various lengths to suit different needs, from a few feet to several hundred feet.

Binder Specifications

1. Type:

– Ratchet Binder: Uses a ratcheting mechanism to tighten and secure loads.

– Lever Binder: Uses a lever action to tighten and secure loads.

2. Material: Typically made from forged steel for high strength and durability.

3. Size Compatibility: Specifies the chain size range the binder is designed to work with (e.g., 5/16″-3/8″).

4. Working Load Limit (WLL): Indicates the maximum weight the binder can safely secure. It’s crucial to match this with the chain’s WLL.

5. Handle Length: The length of the handle can affect the ease of use and leverage provided by the binder.

6. Compliance Standards: Ensure binders meet safety standards such as ASTM and OSHA requirements.

Application and Safety

– Inspection: Regularly inspect chains and binders for wear, deformation, or damage. Replace any components showing signs of excessive wear or damage.

– Usage: Always adhere to manufacturer specifications for load limits and proper securing techniques.

– Storage: Store chains and binders in a dry, clean environment to prevent rust and degradation.

By following these specifications, users can ensure the safe and effective use of chains and binders in various applications.

Applications of chain and binder

Chains and binders are essential tools in various industries for securing loads and ensuring safe transportation. Here are some key applications:

1. Transportation and Logistics: Chains and binders are commonly used to secure heavy cargo on trucks, trailers, and shipping containers. They prevent the load from shifting during transit, reducing the risk of accidents and damage.

2. Construction: In construction, chains and binders secure building materials, such as steel beams, machinery, and equipment, during transport to and around the site. They ensure that heavy items are stable and safely handled by cranes or other lifting equipment.

3. Agriculture: Farmers use chains and binders to secure equipment, such as tractors and harvesters, on flatbed trailers. They also tie down large bales of hay and other bulk materials during transport.

4. Mining: In mining, chains and binders are used to secure heavy machinery and equipment during transport. They also stabilize loads of extracted materials, like ores and minerals, on trucks and railcars.

5. Forestry: Chains and binders secure logs and timber on trucks. Given the irregular shape and weight of logs, proper securing methods are crucial to prevent load shifts and ensure safety.

6. Military and Defense: The military uses chains and binders to secure vehicles, artillery, and equipment during transport. They ensure that all items are securely fastened, whether being transported by land, sea, or air.

7. Rail Transport: Chains and binders are used to secure various types of cargo on railcars. This includes heavy machinery, vehicles, and bulk materials, ensuring they remain stable during rail transit.

8. Emergency Services: Chains and binders are employed by emergency services to stabilize vehicles involved in accidents. They also secure heavy rescue equipment during transport.

In all these applications, the primary goal of using chains and binders is to ensure the safe and secure transport of heavy and potentially hazardous loads, preventing accidents and ensuring the integrity of the cargo.

Material of chain and binder

Chains and binders are critical components in various applications, from securing cargo to machinery operations. The choice of material for both chains and binders significantly impacts their performance, durability, and suitability for specific tasks.

Materials for Chains

1. Steel:

– Carbon Steel: Widely used due to its strength and affordability. Suitable for general-purpose applications.

– Alloy Steel: Enhanced with elements like chromium and molybdenum for higher strength, toughness, and wear resistance. Ideal for heavy-duty applications.

– Stainless Steel: Contains chromium, offering excellent corrosion resistance. Suitable for environments exposed to moisture, chemicals, and high temperatures.

2. Other Metals:

– Aluminum: Lightweight and corrosion-resistant but not as strong as steel. Used in specific applications where weight is a concern.

– Titanium: Exceptional strength-to-weight ratio and corrosion resistance. Used in specialized high-performance applications.

Materials for Binders

1. Steel:

– Carbon Steel: Commonly used for its strength and cost-effectiveness. Suitable for general binding purposes.

– Alloy Steel: Offers higher strength and durability, often used in more demanding applications.

– Stainless Steel: Provides excellent corrosion resistance, ideal for outdoor or corrosive environments.

2. Synthetic Materials:

– Nylon: Lightweight, strong, and resistant to stretching. Used in situations where some flexibility and shock absorption are beneficial.

– Polyester: Similar to nylon but with less stretch and better resistance to UV rays and abrasion. Commonly used in cargo straps and lighter binders.

Considerations

When selecting materials for chains and binders, consider factors such as:

– Load Capacity: Ensure the material can handle the maximum load.

– Environment: Choose materials resistant to environmental factors like corrosion and extreme temperatures.

– Durability: Opt for materials that provide the necessary longevity and resistance to wear and tear.

By carefully choosing the appropriate materials for chains and binders, you can ensure safety, efficiency, and longevity in their application.

Quality Testing Methods for chain and binder and how to control the quality

Quality testing for chains and binders is essential to ensure safety and reliability. Here are some key methods and controls:

Chain Testing Methods:

1. Tensile Testing: Measures the maximum load a chain can withstand before breaking. This test ensures the chain meets the required strength standards.

2. Fatigue Testing: Assesses the chain’s endurance under cyclic loading to determine its lifespan.

3. Dimensional Inspection: Checks the chain links’ dimensions, including length, width, and thickness, to ensure they meet specifications.

4. Non-destructive Testing (NDT): Methods such as ultrasonic or magnetic particle testing detect internal or surface defects without damaging the chain.

5. Corrosion Resistance Testing: Exposes chains to corrosive environments to evaluate their resistance to rust and other forms of degradation.

Binder Testing Methods:

1. Tensile Testing: Determines the binder’s maximum load capacity.

2. Operational Testing: Simulates real-world use to ensure the binder functions correctly under load.

3. Material Analysis: Confirms the binder’s material composition to ensure it meets specified standards.

4. Dimensional and Visual Inspection: Ensures the binder’s components are accurately manufactured and free of defects.

Quality Control Measures:

1. Standardized Procedures: Implement industry standards such as ASTM or ISO for consistent testing and quality benchmarks.

2. Regular Calibration: Ensure testing equipment is regularly calibrated to maintain accuracy.

3. Statistical Process Control (SPC): Use SPC tools to monitor manufacturing processes and identify variations that could affect quality.

4. Documentation and Traceability: Maintain detailed records of materials, processes, and test results for traceability and accountability.

5. Supplier Quality Management: Evaluate and monitor suppliers to ensure the raw materials and components meet quality requirements.

6. Training and Certification: Ensure personnel are trained and certified in quality testing and control procedures.

By applying these testing methods and quality control measures, manufacturers can ensure that chains and binders meet safety and performance standards, reducing the risk of failure in practical applications.

The Work Process and how to use chain and binder

The work process involving chains and binders is crucial in securing heavy loads for transport. Here’s a concise guide:

Work Process:

1. Preparation:

– Inspect Equipment: Check chains and binders for any damage or wear.

– Determine Load Requirements: Calculate the load’s weight and securement points.

2. Positioning the Load:

– Center the Load: Place the load evenly on the transport vehicle to ensure stability.

– Use Blocking: If necessary, use wooden blocks or other materials to prevent load movement.

3. Securing the Load:

– Attach Chains: Hook chains to the securement points on the vehicle and load.

– Position Binders: Place binders (ratchet or lever type) in accessible locations for tightening.

4. Tightening Chains:

– Ratchet Binders: Turn the ratchet handle to tighten the chain. These provide better control and tension.

– Lever Binders: Pull the lever to tighten the chain. Ensure a secure grip and avoid sudden jerks to prevent injury.

5. Inspection:

– Check Tension: Ensure chains are tight and the load is immobile.

– Double-Check Connections: Verify all hooks, links, and binders are properly engaged and locked.

6. Final Adjustments:

– Re-Tighten if Needed: After a short distance, stop and recheck the load. Chains may settle, requiring re-tightening.

Safety Tips:

– Wear Protective Gear: Use gloves and safety glasses to protect against potential injuries.

– Avoid Over-Tightening: Over-tensioning can damage chains and the load.

– Proper Handling: Use correct lifting techniques to avoid strain when handling chains and binders.

By following these steps and safety tips, you can effectively use chains and binders to secure loads, ensuring safe and compliant transport.

chain and binder Importing questions including Cost,Supplier,Sample,Certification and Market

When importing chains and binders, consider the following aspects:

1. Cost:

– Product Cost: Determine the price per unit, including any bulk discounts.

– Shipping Costs: Consider freight charges, import duties, and taxes.

– Hidden Costs: Account for insurance, customs clearance fees, and storage.

2. Supplier:

– Reliability: Research the supplier’s reputation, reliability, and reviews from other buyers.

– Experience: Evaluate their experience in exporting to your country.

– Support: Assess the level of customer service and after-sales support.

3. Sample:

– Request Samples: Always ask for product samples to assess quality.

– Sample Cost: Determine if the supplier charges for samples and whether this cost is refundable upon order placement.

– Lead Time: Check the time required to deliver samples.

4. Certification:

– Compliance: Ensure the products meet the regulatory standards and safety certifications required in your country.

– Documentation: Obtain all necessary certificates, like ISO, CE, or other relevant quality standards.

– Verification: Confirm the authenticity of certificates through relevant authorities or third-party verification.

5. Market:

– Demand Analysis: Study the market demand for chains and binders in your region.

– Competition: Analyze competitors’ pricing, quality, and market share.

– Target Audience: Identify your primary customer base and tailor your marketing strategies accordingly.

Effective importation involves thorough research and strategic planning to ensure cost-efficiency, quality, and compliance with regulations. Building a good relationship with a reliable supplier is crucial for long-term success.

How to find and select check reliable chain and binder manufacturers in China

Finding and selecting reliable chain and binder manufacturers in China involves several steps:

1. Online Directories and Marketplaces:

– Alibaba: Start with Alibaba.com, a leading B2B marketplace. Search for “chain and binder manufacturers” and filter results by verified suppliers.

– Made-in-China: Another reputable platform to find Chinese manufacturers. Look for high-rated and verified suppliers.

2. Supplier Verification:

– Certifications: Check for ISO certifications and other industry-specific certifications.

– Product Samples: Request product samples to assess quality.

– Factory Visits: If possible, visit the factories to inspect their operations and production capabilities.

3. Third-Party Inspections and Audits:

– Use third-party inspection companies such as SGS or Bureau Veritas to conduct factory audits and quality inspections.

4. Trade Shows and Exhibitions:

– Attend trade shows like the Canton Fair or China International Hardware Show to meet manufacturers in person and see their products firsthand.

5. Reviews and References:

– Look for reviews and testimonials from other businesses. Ask the manufacturers for references and follow up with their previous clients.

6. Negotiation and Contracts:

– Negotiate terms clearly, including payment terms, delivery schedules, and quality standards.

– Ensure contracts are detailed and legally binding, possibly seeking legal assistance to review the terms.

7. Sample Order:

– Place a small initial order to test the manufacturer’s reliability, product quality, and delivery efficiency.

8. Long-term Relationship:

– Build a long-term relationship with the manufacturer to ensure ongoing reliability and potential for better pricing and terms.

By following these steps, you can effectively identify and select reliable chain and binder manufacturers in China.

Background Research for chain and binder manufacturers Companies in China, use qcc.com archive.org importyeti.com

In China, several prominent companies specialize in the manufacture of chains and binders. Utilizing sources like Qcc.com, Archive.org, and ImportYeti.com, the following key manufacturers stand out:

1. Shanghai Yiying Lifting Machinery Co., Ltd.: Located in Shanghai, this company is a significant player in the production of lifting chains, binders, and related equipment. They have a strong presence in the domestic market and have been expanding their international reach through exports.

2. Qingdao Dazheng Jin Hao Chain Co., Ltd.: Based in Qingdao, this company is well-regarded for its high-quality chains used in various industrial applications. They emphasize innovation and have a robust R&D department to continuously improve their products.

3. Nantong Shenwei Steel Wire Rope Co., Ltd.: Situated in Jiangsu province, this company focuses on producing chains and wire ropes. They are known for their stringent quality control processes and have obtained numerous certifications that make them a preferred supplier for many international clients.

These companies are recognized for their extensive product ranges and commitment to quality. They have established themselves as leaders in their field through continuous innovation and by meeting both domestic and international standards.

For further details, you can explore their profiles on platforms like Qcc.com, which provide comprehensive business information and company histories, or ImportYeti.com for data on their export activities. Archive.org also hosts historical data that can offer insights into the development and growth of these companies over time.

Price Cost Research for chain and binder manufacturers Companies in China, use temu.com and 1688.com

For research on chain and binder manufacturers in China, using Temu and 1688.com, here are some insights:

Temu.com

1. Tow Chain Binder Sets: On Temu, a set consisting of a 5/16″ – 3/8″ chain binder and 10ft chains, grade 70, is priced at $42.47. This set is suitable for industrial, agricultural, logging, and towing applications.

2. Ratchet Load Binders: Another listing features 1/4 inch ratchet load binders with a working strength of up to 2600 lbs and a breaking strength of 9200 lbs, priced competitively.

3. General Binder Chains: There are various binder chains available, with options for different applications and strengths. Prices vary depending on specifications and quantities.

1688.com

1. Manufacturers and Prices: 1688.com lists numerous manufacturers offering competitive prices for bulk purchases of chain and binder products. For example, heavy-duty ratchet load binders can range from $20 to $50 per unit depending on the order size and specifications.

2. Customization: Many suppliers on 1688.com offer customization options for chain lengths, binder capacities, and finishes, catering to specific industrial needs. This flexibility can be crucial for businesses requiring tailored solutions.

Both platforms provide a range of products at different price points, with 1688.com being more oriented towards bulk and wholesale purchases, often at lower per-unit costs due to the scale. Temu, on the other hand, offers more straightforward retail options with free shipping and returns policies, making it convenient for smaller orders.

For precise details and the latest prices, visiting the respective product pages on Temu and 1688.com will provide the most accurate and current information.

Shipping Cost for chain and binder import from China

Importing chains and binders from China involves several cost components that need to be considered to estimate the total shipping cost accurately. Here are the key factors:

1. Freight Cost: This is the primary cost, determined by the shipping method—air, sea, or land. Sea freight is the most economical for heavy and bulky items like chains and binders. Costs depend on container size (e.g., 20-foot or 40-foot containers) and weight. Current rates can range from $1,000 to $5,000 per container.

2. Customs Duties and Taxes: Import duties vary by country and product type. For chains and binders, check the Harmonized System (HS) code to determine the specific tariff rate. For example, the U.S. may impose duties ranging from 2.5% to 5% of the shipment value.

3. Insurance: Cargo insurance protects against loss or damage during transit. It typically costs between 0.5% and 2% of the cargo’s value.

4. Handling Fees: These include port handling fees, terminal charges, and other logistics-related costs. These fees can add $100 to $500 per container.

5. Documentation Fees: Costs for required documents such as Bill of Lading, commercial invoice, packing list, and certificates of origin. These fees generally range from $50 to $200.

6. Domestic Transport: Costs to move the shipment from the destination port to the final destination. This can vary widely depending on distance and mode of transportation.

7. Other Fees: Warehousing, storage, and possible demurrage charges if the cargo isn’t cleared from the port on time.

To get a precise estimate, it’s recommended to contact freight forwarders for detailed quotes based on specific shipment details. Use online calculators for a rough estimate but ensure to get detailed and current rates for accuracy.

Compare China and Other chain and binder Markets: Products Quality and Price,Visible and Hidden Costs

Comparison of Chain and Binder Markets: China vs. Others

Products Quality and Price:

Chinese chain and binder products are typically known for their competitive pricing. This affordability often stems from lower labor costs and mass production capabilities. However, the quality can vary significantly. Some Chinese manufacturers produce high-quality items that meet international standards, while others might offer lower-grade products to cut costs.

In contrast, products from markets like the US, Germany, and Japan are often higher in price but also in quality. These countries tend to have stricter quality control measures and use superior materials, ensuring durability and reliability. For example, German chains are renowned for their precision engineering and long lifespan.

Visible and Hidden Costs:

Visible costs are the upfront expenses like the purchase price. Chinese products generally have lower visible costs, making them attractive for budget-conscious buyers.

Hidden costs include factors such as shipping, import duties, maintenance, and replacement frequency. Chinese products might incur higher hidden costs if their quality is inconsistent, leading to more frequent replacements and higher maintenance expenses. Additionally, long shipping times and potential delays can add to the hidden costs.

On the other hand, products from other markets might have higher visible costs but potentially lower hidden costs due to better durability and less frequent need for replacement. These products often come with more reliable warranties and after-sales service, further reducing long-term expenses.

Conclusion:

Choosing between Chinese chain and binder products and those from other markets involves balancing initial cost savings with potential long-term reliability and hidden costs. While Chinese products can be cost-effective upfront, higher-quality options from markets like the US, Germany, and Japan may offer better value over time due to their superior quality and lower hidden costs.

Custom Private Labeling and Branding Opportunities with Chinese chain and binder Manufacturers

Custom private labeling and branding opportunities with Chinese chain and binder manufacturers offer a cost-effective and scalable solution for businesses looking to enhance their product offerings. These manufacturers provide a wide array of customization options, allowing companies to tailor products to their specific brand requirements and market needs.

Benefits

1. Cost Efficiency: Manufacturing in China is often more cost-effective due to lower labor costs and economies of scale. This allows businesses to maintain high-quality standards while keeping expenses low.

2. High-Quality Products: Many Chinese manufacturers adhere to stringent quality control standards, ensuring that products meet international certifications and customer expectations.

3. Customization Options: From logo printing to unique packaging designs, manufacturers offer extensive customization options. This includes selecting materials, finishes, colors, and sizes to match brand aesthetics.

4. Scalability: Chinese manufacturers can handle large orders, making it easier for businesses to scale up production as demand grows. They also offer flexibility in small batch productions for niche markets.

5. Advanced Technology: Many Chinese manufacturers invest in advanced manufacturing technologies, providing innovative solutions and efficient production processes that enhance product quality and consistency.

Key Considerations

1. Supplier Verification: It’s crucial to verify the credibility of the manufacturer. This can be done through factory visits, third-party audits, and checking references from other businesses.

2. Clear Communication: Establishing clear and consistent communication channels is vital. This ensures that all product specifications, quality standards, and branding requirements are understood and met.

3. Intellectual Property Protection: Ensure that your intellectual property, including designs and logos, is protected through appropriate legal agreements.

4. Lead Times: Be aware of production and shipping lead times to plan inventory effectively and meet market demands.

Partnering with Chinese chain and binder manufacturers for custom private labeling and branding can significantly boost a brand’s market presence, offering high-quality, cost-effective solutions tailored to specific business needs.

Tips for Procurement and Considerations when Purchasing chain and binder

Tips for Procurement and Considerations for Purchasing Chain and Binder

1. Understand the Requirements:

– Load Capacity: Determine the maximum load weight to ensure the chain and binder can handle it.

– Material: Choose between steel or alloy chains based on strength, durability, and environmental exposure.

2. Quality and Standards:

– Compliance: Ensure the chains and binders meet industry standards such as ASTM, OSHA, and ISO.

– Manufacturer Reputation: Select products from reputable manufacturers known for quality and reliability.

3. Type of Chain and Binder:

– Chains: Decide between types like Grade 70 transport chain, Grade 80 alloy chain, or Grade 100 lifting chain based on the application.

– Binders: Choose between ratchet binders for ease of tightening and lever binders for quick operation.

4. Safety Features:

– Load Markings: Ensure the chain and binder have clear load markings.

– Inspection and Maintenance: Consider the ease of inspecting and maintaining the chains and binders.

5. Cost Efficiency:

– Bulk Purchasing: Evaluate the benefits of bulk purchasing for cost savings.

– Lifecycle Cost: Consider the total cost of ownership, including purchase price, maintenance, and replacement costs.

6. Supplier Relationship:

– Reliability: Work with suppliers who offer reliable delivery schedules.

– Support: Ensure the supplier provides good after-sales support, including warranty and replacement services.

7. Environmental Conditions:

– Corrosion Resistance: For outdoor or harsh environments, opt for chains with corrosion-resistant coatings like galvanization or stainless steel.

8. Ease of Use:

– Ergonomics: Choose binders that are easy to operate and reduce operator fatigue.

– Training: Ensure staff is properly trained on the use and safety of chains and binders.

By focusing on these considerations, you can make informed procurement decisions that ensure safety, compliance, and cost-effectiveness.

FAQs on Sourcing and Manufacturing chain and binder in China

FAQs on Sourcing and Manufacturing Chain and Binder in China

#### 1. Why source chain and binder products from China?

China offers a robust manufacturing infrastructure, competitive pricing, and a vast array of suppliers, making it a cost-effective and efficient option for sourcing chain and binder products.

#### 2. What are the key considerations when selecting a supplier in China?

Key considerations include the supplier’s manufacturing capabilities, quality control processes, certifications (like ISO), production capacity, and experience in exporting goods. Visiting the factory or requesting samples can also be beneficial.

#### 3. How can I ensure the quality of products?

Quality can be ensured by setting clear specifications, conducting thorough inspections, and hiring third-party quality control agencies. Establishing long-term relationships with reliable suppliers also helps maintain quality standards.

#### 4. What are the common challenges in sourcing from China?

Common challenges include language barriers, cultural differences, time zone differences, and logistics complexities. Additionally, intellectual property protection and ensuring consistent product quality can be challenging.

#### 5. How do I handle logistics and shipping?

Logistics can be managed through freight forwarders or third-party logistics (3PL) companies. They handle transportation, customs clearance, and delivery. Choosing the right incoterms (e.g., FOB, CIF) is crucial for defining responsibilities between buyer and seller.

#### 6. What payment methods are commonly used?

Common payment methods include wire transfers (T/T), Letters of Credit (L/C), and online payment platforms like Alibaba Trade Assurance. Payment terms can vary, with some suppliers requiring partial upfront payments.

#### 7. Are there any regulatory requirements?

Yes, understanding both the Chinese export regulations and the import regulations of your country is essential. This includes compliance with safety standards, labeling requirements, and any specific industry regulations.

#### 8. What role do trade shows and online platforms play?

Trade shows like the Canton Fair and online platforms like Alibaba and Made-in-China are valuable resources for finding suppliers, comparing products, and initiating contact.

By considering these factors, businesses can effectively navigate the complexities of sourcing and manufacturing chain and binder products in China.