Top 10 butterfly valve seal in China introduce,list main products and website if have

Here are ten notable butterfly valve seal manufacturers in China, along with their main products and websites:

1. XHVAL Valve Co., Ltd.

– Main Products: Butterfly valves, gate valves, ball valves, and check valves.

– Website: [xhval.com](https://www.xhval.com)

2. Dixon Valve & Coupling Company (China)

– Main Products: Butterfly valves, hose fittings, quick couplings, and clamps.

– Website: [dixonvalve.com](https://www.dixonvalve.com)

3. Zhejiang Xinhai Valve Manufacturing Co., Ltd.

– Main Products: Butterfly valves, gate valves, ball valves, and check valves.

– Website: [xhval.com.cn](http://www.xhval.com.cn)

4. Hebei Tongli Automatic Control Valve Manufacturing Co., Ltd.

– Main Products: Butterfly valves, gate valves, control valves, and ball valves.

– Website: [tlvalves.com](http://www.tlvalves.com)

5. China Valve Industry Co., Ltd.

– Main Products: Butterfly valves, gate valves, ball valves, and globe valves.

– Website: [chinavalve.com](http://www.chinavalve.com)

6. Yuanda Valve Group Co., Ltd.

– Main Products: Butterfly valves, gate valves, ball valves, and check valves.

– Website: [yuandavalve.com](http://www.yuandavalve.com)

7. Neway Valve (Suzhou) Co., Ltd.

– Main Products: Butterfly valves, ball valves, gate valves, and globe valves.

– Website: [newayvalve.com](http://www.newayvalve.com)

8. China Lutong Parts Plant

– Main Products: Butterfly valves, injection pump parts, and fuel system parts.

– Website: [dieselpartsworld.com](http://www.dieselpartsworld.com)

9. Chengdu Xingyu Precision Casting Co., Ltd.

– Main Products: Butterfly valves, precision castings, and stainless steel valves.

– Website: [cdxingyu.com](http://www.cdxingyu.com)

10. Wuzhou Valve Co., Ltd.

– Main Products: Butterfly valves, ball valves, gate valves, and check valves.

– Website: [wzvalve.com](http://www.wzvalve.com)

These companies are known for their quality products and extensive ranges of butterfly valve seals and other industrial valve solutions.

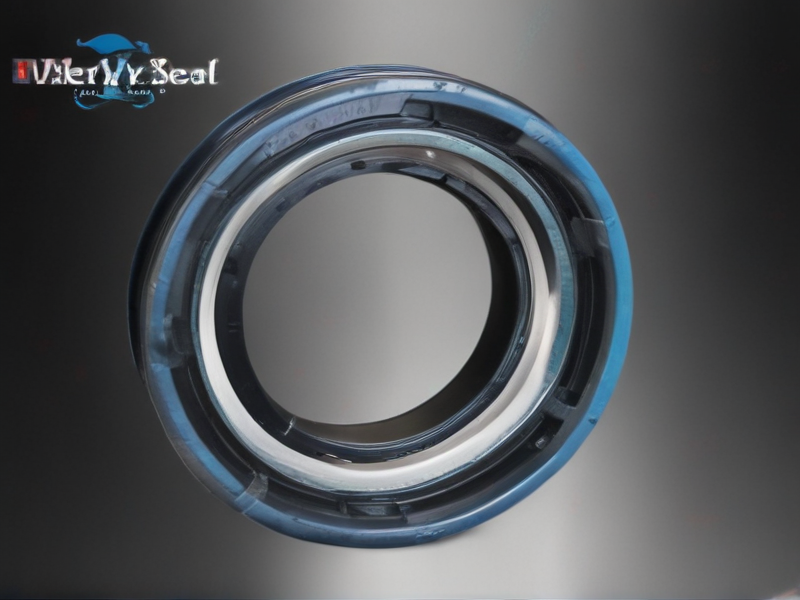

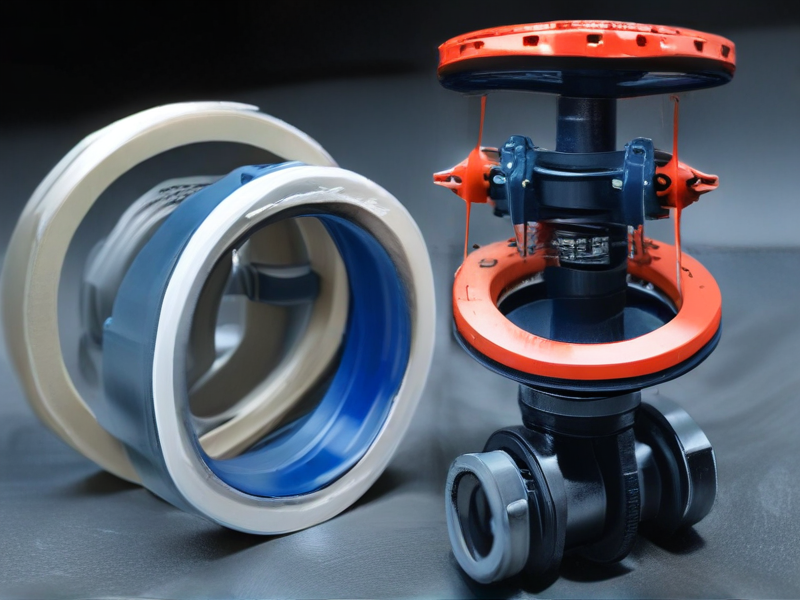

Types of butterfly valve seal

Butterfly valve seals are crucial for ensuring leak-free operation and come in various types to accommodate different applications and materials. Here are the main types:

1. Resilient Seated Seals:

– Rubber Seals: Commonly made from EPDM, NBR, or silicone, these seals are used for general applications where flexibility and resilience are required. They provide a tight seal and are suitable for low to moderate pressure systems.

– PTFE Seals: PTFE (Teflon) seals offer excellent chemical resistance and are suitable for corrosive environments. They are used in applications requiring high temperature and chemical compatibility.

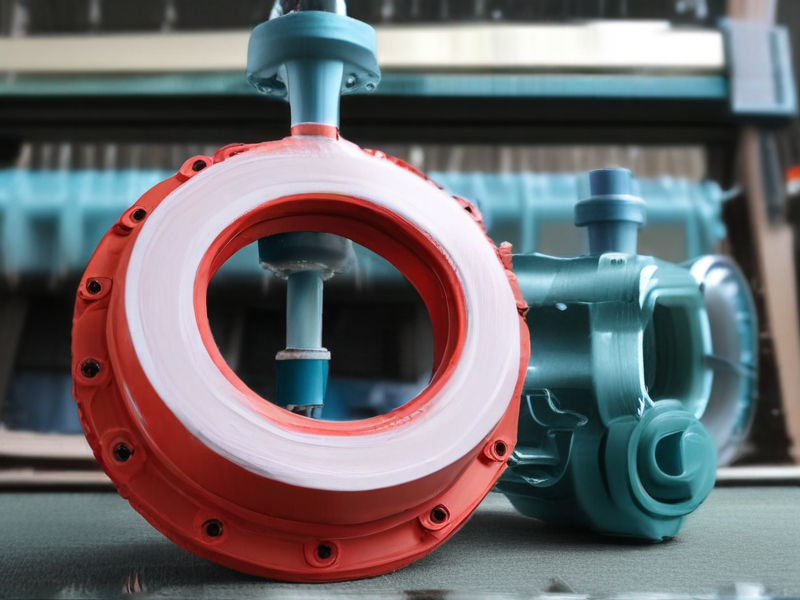

2. High-Performance Seals:

– Metal Seals: These include seals made from stainless steel or other alloys. They are designed for high-pressure and high-temperature applications. Metal seals are less flexible but provide a robust, durable seal under extreme conditions.

– Composite Seals: Combining materials like PTFE with a metallic core, these seals offer a balance between flexibility and strength, suitable for high-performance applications where chemical resistance and durability are required.

3. Triple Offset Seals:

– Laminated Seals: Used in triple offset butterfly valves, laminated seals consist of multiple layers of metal and graphite or PTFE. They provide a tight seal in high-pressure and high-temperature environments, often used in critical applications like petrochemical and power generation industries.

4. Inflatable Seals:

– These seals use an elastomer that can be inflated to create a seal, providing excellent sealing properties in applications where a tight shutoff is critical, such as in isolation valves in the pharmaceutical and food industries.

Each type of seal has its own advantages and limitations, making it essential to choose the right seal based on the specific operating conditions and requirements of the application.

Pros and Cons of Using butterfly valve seal

Butterfly valve seals are critical components in butterfly valves, used to regulate flow in pipelines. Here are the main pros and cons of using butterfly valve seals:

Pros

1. Cost-Effective: Butterfly valves and their seals are generally more affordable compared to other valve types, making them a cost-efficient option for many applications.

2. Compact Design: Their smaller size and lighter weight reduce installation space and support structure requirements, leading to easier handling and installation.

3. Quick Operation: They offer swift opening and closing, enhancing process control and operational efficiency.

4. Versatility: Suitable for a wide range of fluids, including gases, liquids, and semi-solids, and can operate under various pressure and temperature conditions.

5. Low Maintenance: The simplicity of the butterfly valve design translates to minimal maintenance, reducing downtime and maintenance costs.

Cons

1. Sealing Limitations: Butterfly valve seals might not provide as tight a seal as other valves, like ball valves, potentially leading to leakage, especially under high pressure or vacuum conditions.

2. Pressure Drop: The presence of the valve disc in the flow path can cause a higher pressure drop compared to other valves, which might impact system efficiency.

3. Limited for High Pressure: They are generally not suitable for very high-pressure applications, as the seal and disc might deform under extreme pressure.

4. Not Ideal for Slurry: In applications involving slurries or fluids with solid particles, the seal can wear out quickly due to abrasion, leading to frequent replacements.

5. Potential for Cavitation: In high-velocity flow scenarios, butterfly valves can be prone to cavitation, which can damage the seal and reduce valve lifespan.

Butterfly valve seals are advantageous for their cost, ease of use, and low maintenance but may face challenges in sealing effectiveness and handling extreme conditions.

butterfly valve seal Reference Specifications (varies for different product)

Butterfly valve seals are critical components that ensure the proper functioning and sealing of butterfly valves. The specifications for these seals vary depending on the application, material, and design requirements. Here are some key reference specifications to consider:

1. Material:

– Elastomers: EPDM, NBR, FKM (Viton), and Silicone.

– Plastics: PTFE, PEEK.

– Metals: Stainless steel, Inconel, Hastelloy.

2. Temperature Range:

– Elastomeric seals: -30°C to 200°C, depending on the material.

– PTFE and other high-performance plastics: up to 260°C.

– Metal seals: up to 500°C and beyond for special applications.

3. Pressure Rating:

– Low-pressure applications: up to 10 bar.

– Medium-pressure applications: 10-25 bar.

– High-pressure applications: above 25 bar.

4. Chemical Compatibility:

– Chemical resistance varies by material. For example, EPDM is suitable for water and steam, while FKM is better for oils and fuels.

– PTFE offers excellent chemical resistance to most chemicals.

5. Design Standards:

– ASME B16.34: Valves – Flanged, Threaded, and Welding End.

– API 609: Butterfly Valves: Double Flanged, Lug- and Wafer-Type.

– ISO 5752: Metal Valves for Use in Flanged Pipe Systems – Face-to-Face and Center-to-Face Dimensions.

6. Seal Types:

– Resilient Seated: Soft seals providing tight shutoff, commonly used in low-pressure systems.

– High-Performance: Utilizes a PTFE or metal seat for higher pressures and temperatures.

– Triple Offset: Metal-to-metal sealing suitable for high-temperature and high-pressure applications.

7. Application-Specific Requirements:

– Food and beverage: FDA and EU 1935/2004 compliant materials.

– Pharmaceutical: USP Class VI certified elastomers.

– Oil and Gas: NACE MR0175/ISO 15156 compliance for sour gas service.

These specifications ensure that butterfly valve seals meet the diverse needs of various industries, providing reliable performance under different operating conditions.

Applications of butterfly valve seal

Butterfly valve seals are crucial in various applications due to their ability to regulate and isolate fluid flow with a simple yet effective mechanism. Here are some key applications:

1. Water Treatment and Distribution:

– Butterfly valves are extensively used in water treatment plants for flow regulation and isolation. Their compact design and quick operation make them ideal for controlling water distribution in municipal and industrial systems.

2. HVAC Systems:

– In heating, ventilation, and air conditioning (HVAC) systems, butterfly valve seals ensure efficient flow control of air, water, and other fluids. They help maintain desired temperatures and air quality in commercial and residential buildings.

3. Oil and Gas Industry:

– These valves are employed in pipelines and processing plants to manage the flow of crude oil, natural gas, and refined products. Their ability to handle high pressures and temperatures is critical in this sector.

4. Chemical Processing:

– Butterfly valves are used to control the flow of various chemicals, ensuring precise handling and safety. The seals must be resistant to corrosion and chemical reactions, making them suitable for aggressive fluids.

5. Food and Beverage Industry:

– Hygienic butterfly valves, with seals made from food-grade materials, are essential in processing and packaging food and beverages. They ensure contamination-free and efficient flow control.

6. Pulp and Paper Industry:

– In pulp and paper mills, butterfly valves regulate the flow of water, pulp, and chemicals used in the manufacturing process. Their durability and ease of maintenance are beneficial in these harsh environments.

7. Pharmaceuticals:

– High-purity butterfly valves with specialized seals are used in pharmaceutical manufacturing to handle fluids and gases. They meet stringent sanitary standards and prevent contamination.

8. Power Generation:

– In power plants, butterfly valves manage the flow of steam, cooling water, and fuel. Their reliable performance under extreme conditions supports efficient power generation.

Butterfly valve seals play a pivotal role in diverse industries by providing reliable and efficient flow control, contributing to operational efficiency and safety.

Material of butterfly valve seal

Butterfly valve seals are critical components designed to provide tight shut-off and control fluid flow. The material selection for these seals depends on the application, including the type of fluid, operating temperature, and pressure conditions. Common materials used for butterfly valve seals include:

1. EPDM (Ethylene Propylene Diene Monomer): Ideal for water, steam, and some chemical applications. EPDM is highly resistant to weathering, ozone, and UV radiation, with a temperature range of -40°C to 120°C.

2. NBR (Nitrile Butadiene Rubber): Suitable for oil, fuel, and other hydrocarbon applications. NBR offers good resistance to wear and abrasion, with an operational temperature range of -30°C to 100°C.

3. FKM (Fluoroelastomer, commonly known as Viton): Used in chemical processing, oil and gas, and high-temperature applications due to its excellent resistance to chemicals, oils, and heat, with a temperature range up to 200°C.

4. PTFE (Polytetrafluoroethylene, commonly known as Teflon): Provides excellent chemical resistance and a broad temperature range (-200°C to 250°C). PTFE is used in aggressive chemical environments and where high purity is required.

5. Silicone: Suitable for food and pharmaceutical applications due to its excellent flexibility and low toxicity. Silicone operates effectively within a temperature range of -60°C to 180°C.

6. Metal Seals (Stainless Steel, Inconel, etc.): Used in high-pressure and high-temperature applications where elastomers are unsuitable. Metal seals provide superior strength and durability.

Each material has unique properties that make it suitable for specific conditions. The choice depends on factors such as the nature of the fluid, environmental conditions, regulatory requirements, and cost considerations. Proper material selection ensures the valve’s performance, longevity, and safety in its intended application.

Quality Testing Methods for butterfly valve seal and how to control the quality

Quality testing methods for butterfly valve seals focus on ensuring they meet performance and safety standards. Here are key methods:

1. Visual Inspection:

– Purpose: Identifies surface defects, such as cracks or tears.

– Procedure: Inspect seals under good lighting, using magnification tools if necessary.

2. Dimensional Inspection:

– Purpose: Ensures seals meet specified dimensions and tolerances.

– Procedure: Use calipers, micrometers, and coordinate measuring machines (CMM).

3. Leakage Test:

– Purpose: Assesses the seal’s ability to prevent fluid leakage.

– Procedure: Subject the valve to a specific pressure and check for leaks using air or water under pressure.

4. Pressure Test:

– Purpose: Verifies seal integrity under operating pressures.

– Procedure: Test the valve at various pressure levels, typically exceeding operational conditions.

5. Material Hardness Test:

– Purpose: Ensures the material meets hardness specifications.

– Procedure: Use a durometer to measure the hardness of the seal material.

6. Temperature Resistance Test:

– Purpose: Evaluates performance under varying temperature conditions.

– Procedure: Expose the seal to high and low temperatures and check for deformation or loss of elasticity.

7. Chemical Resistance Test:

– Purpose: Assesses seal performance in contact with various chemicals.

– Procedure: Immerse the seal in different chemicals and inspect for degradation.

8. Life Cycle Test:

– Purpose: Estimates the durability and lifespan of the seal.

– Procedure: Operate the valve through numerous open/close cycles and inspect for wear.

Quality Control Measures

1. Standard Operating Procedures (SOPs):

– Establish detailed SOPs for each testing method to ensure consistency.

2. Training and Certification:

– Train personnel thoroughly and ensure they are certified in inspection techniques.

3. Statistical Process Control (SPC):

– Use SPC to monitor production and identify variations that could affect seal quality.

4. Documentation and Traceability:

– Maintain detailed records of all inspections and tests for traceability and accountability.

5. Regular Calibration of Equipment:

– Ensure all testing equipment is regularly calibrated to maintain accuracy.

By employing these methods and control measures, the quality of butterfly valve seals can be effectively ensured and maintained.

The Work Process and how to use butterfly valve seal

Work Process of Butterfly Valve Seal

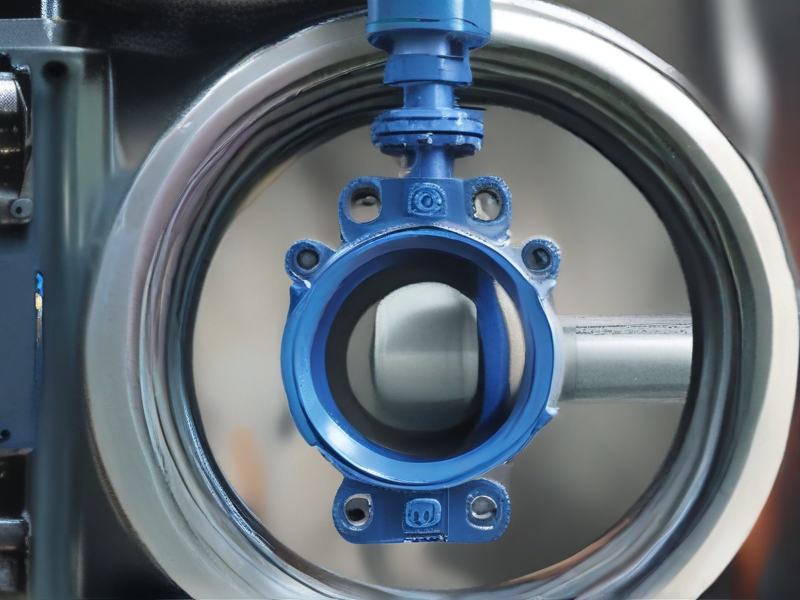

A butterfly valve is a type of quarter-turn valve used to regulate flow. The work process involves a disk mounted on a rotating shaft. When the valve is fully closed, the disk blocks the valve bore, and when fully open, the disk aligns parallel to the flow.

Components:

1. Body: Houses the valve and flow passage.

2. Disk: The rotating element controlling flow.

3. Shaft: Connects the disk to the actuator.

4. Seat: Provides a sealing surface for the disk.

5. Actuator: Operates the shaft and disk.

Work Process:

1. Installation: Mount the valve in the pipeline ensuring alignment with the flow direction.

2. Connection: Attach the actuator to the valve’s shaft.

3. Operation:

– Open Position: Rotate the actuator 90 degrees to align the disk with the flow, allowing fluid to pass.

– Closed Position: Rotate the actuator back 90 degrees to position the disk perpendicular to the flow, stopping the fluid.

Using Butterfly Valve Seal

The seal in a butterfly valve is crucial for preventing leaks. Here’s how to use it effectively:

1. Material Selection: Choose a seal material compatible with the fluid type and operating conditions (e.g., EPDM, NBR, PTFE).

2. Inspection: Before installation, check the seal for any defects or wear.

3. Installation:

– Ensure the seat (seal) is properly seated in the valve body.

– Lubricate the seal lightly if specified by the manufacturer.

– Align the disk so it does not damage the seal during operation.

4. Operation:

– Gradually operate the valve to avoid sudden pressure changes that could damage the seal.

– Regularly operate the valve to prevent the seal from sticking or deforming.

5. Maintenance:

– Periodically inspect the seal for wear or damage.

– Replace the seal as per the manufacturer’s recommendations or if any damage is detected.

By following these steps, you can ensure the effective use and longevity of the butterfly valve seal, maintaining efficient flow control and preventing leaks.

butterfly valve seal Importing questions including Cost,Supplier,Sample,Certification and Market

Importing Butterfly Valve Seals: Key Considerations

1. Cost:

– Unit Price: Costs vary depending on material (rubber, PTFE, etc.), size, and quality. Typical prices range from $5 to $50 per unit.

– Shipping: International shipping costs can significantly impact the total cost. Bulk orders might reduce per-unit shipping costs.

– Customs Duties: Be aware of import duties and taxes specific to your country, which can affect overall cost.

2. Supplier:

– Identification: Use platforms like Alibaba, Global Sources, or ThomasNet to find potential suppliers.

– Reputation: Check supplier ratings, reviews, and trade assurance to ensure reliability.

– Communication: Effective communication is crucial. Ensure the supplier can meet your specifications and delivery timelines.

3. Sample:

– Requesting Samples: Before placing a bulk order, request samples to evaluate quality. Most suppliers provide samples for a nominal fee or even for free.

– Evaluation: Assess the sample for material quality, dimensional accuracy, and performance under expected operating conditions.

4. Certification:

– Industry Standards: Ensure the products meet relevant standards (e.g., ISO, ANSI, DIN). Certifications might be required for certain industries, such as food or pharmaceuticals.

– Supplier Documentation: Request certification documents and verify their authenticity. Certifications like ISO 9001 indicate quality management practices.

5. Market:

– Demand Analysis: Understand the demand for butterfly valve seals in your target market. Consider factors like industry requirements and regional regulations.

– Competitive Landscape: Analyze competitors and their offerings to position your product effectively.

– Marketing Strategy: Develop a strategy to promote your valve seals, highlighting quality, certifications, and competitive pricing.

By addressing these aspects, you can make informed decisions when importing butterfly valve seals, ensuring a balance between cost, quality, and compliance.

How to find and select check reliable butterfly valve seal manufacturers in China

Finding and selecting reliable butterfly valve seal manufacturers in China involves several key steps:

1. Research and Identify Potential Manufacturers:

– Online Directories: Use platforms like Alibaba, Made-in-China, and Global Sources to identify manufacturers. Filter by ratings, certifications, and verified status.

– Industry Networks: Join industry-specific forums, LinkedIn groups, and attend virtual trade shows to gather recommendations.

2. Evaluate Credibility:

– Certifications: Look for ISO 9001, CE, or other relevant certifications that indicate quality standards.

– Reviews and References: Check customer reviews and ask for references to understand their reliability and performance.

3. Assess Manufacturing Capabilities:

– Product Range: Ensure the manufacturer offers a range of butterfly valve seals suitable for your application.

– Customization: Verify if they provide customization options to meet specific needs.

– Technology and Equipment: Modern and well-maintained equipment often correlates with better product quality.

4. Quality Control:

– Inspection Processes: Inquire about their quality control processes and if they provide inspection reports.

– Testing Facilities: Check if they have in-house testing facilities to ensure product durability and performance.

5. Communication and Support:

– Responsiveness: Gauge their responsiveness and willingness to communicate during the initial inquiry.

– Language Proficiency: Effective communication is crucial; ensure they have staff proficient in your language.

6. Factory Visits and Audits:

– On-site Visits: If possible, visit the factory to see their operations firsthand.

– Third-party Audits: Use third-party audit services if a personal visit isn’t feasible.

7. Sample Orders:

– Trial Orders: Place a small order first to test the product quality, delivery times, and overall service.

8. Logistics and Legal Aspects:

– Shipping Capabilities: Ensure they have reliable shipping partners and can handle international logistics.

– Contracts: Secure detailed contracts outlining specifications, payment terms, and warranties.

By following these steps, you can effectively identify and select reliable butterfly valve seal manufacturers in China.

Background Research for butterfly valve seal manufacturers Companies in China, use qcc.com archive.org importyeti.com

Several reputable companies in China manufacture butterfly valve seals, as detailed on qcc.com.

1. Zhonghe Su Valve Technology Industrial Co., Ltd.: Established in 1997 and located in Suzhou, this company focuses on manufacturing various types of valves including butterfly valve seals. They are part of the China National Nuclear Corporation (CNNC) and have a large workforce dedicated to production and research【6†source】.

2. Sailcon Technology (Shenzhen) Co., Ltd.: Founded in 1997, this company operates in Shenzhen and specializes in advanced manufacturing technologies. They produce a range of valve seals and have significant experience in the field, supported by a large team and extensive facilities【7†source】.

3. Beijing Kangjiesen Automation Technology Co., Ltd.: Operating since 1999, this Beijing-based company is involved in the automation technology sector, including the manufacturing of high-precision butterfly valve seals. Their expertise lies in integrating advanced automation with valve production【8†source】.

4. Qingdao Chuangxin Qizhi Technology Group Co., Ltd.: Located in Qingdao and founded in 2018, this company is relatively new but rapidly growing in the valve manufacturing industry. They focus on innovative technologies and have a robust production line for various industrial valves, including butterfly valve seals【9†source】.

These companies represent some of the key players in China’s butterfly valve seal manufacturing sector, each bringing a combination of experience, innovation, and scale to the industry.

Price Cost Research for butterfly valve seal manufacturers Companies in China, use temu.com and 1688.com

Here are some manufacturers of butterfly valve seals in China, along with their price ranges from 1688.com and Temu.com:

1. Tianjin Yuanfei Valve Manufacturing Co., Ltd.:

– Example Product: D71X-16Q Soft Seal Butterfly Valve

– Price: Approximately ¥25.27 per unit【7†source】.

2. Tangshan Yicheng Valve Co., Ltd.:

– Example Product: Handwheel Butterfly Valve

– Price: Starting at ¥23.75 per unit【7†source】.

3. Wenzhou Kamanse Valve Business Department:

– Example Product: Stainless Steel Clamp Butterfly Valve

– Price: Around ¥88 per unit【7†source】.

4. Shenzhen Spsk Valve Co., Ltd.:

– Example Product: Pneumatic Butterfly Valve D671X-16Q

– Price: Around ¥666 per unit【7†source】.

These prices provide a snapshot of the cost range for butterfly valve seals from various manufacturers in China.

Shipping Cost for butterfly valve seal import from China

The cost of shipping butterfly valve seals from China to another country involves several factors, including the type of shipping, weight and dimensions of the package, destination, and additional fees. Here’s a breakdown:

1. Shipping Methods:

– Air Freight: Faster but more expensive. Suitable for smaller, urgent shipments.

– Sea Freight: More economical for large, heavy shipments but slower.

– Courier Services: Such as DHL, FedEx, or UPS, ideal for smaller, less bulky shipments.

2. Cost Components:

– Base Shipping Cost: Determined by weight, volume, and shipping method.

– Fuel Surcharges: Vary based on current fuel prices.

– Customs Duties and Taxes: Depend on the destination country’s regulations.

– Insurance: Optional but recommended for valuable shipments.

– Handling Fees: Charges for packaging, labeling, and other handling requirements.

3. Estimate Calculation:

– Weight and Dimensions: Determine the chargeable weight (greater of actual vs. volumetric weight).

– Destination: Costs vary significantly by country and distance from major shipping hubs.

4. Example Cost Estimates:

– Air Freight: Approximately $4-$8 per kilogram for shipments from China to the US or Europe.

– Sea Freight: For a 20-foot container, costs range from $1,000 to $3,000, varying with the specific route and shipping season.

– Courier Services: For a 10 kg package, expect costs around $100-$300 depending on speed and destination.

5. Cost-Saving Tips:

– Consolidate Shipments: To reduce per-unit shipping costs.

– Flexible Timing: Utilize slower shipping methods if time allows.

– Negotiate Rates: Especially for regular, bulk shipments.

For an accurate estimate, consulting with shipping providers or a freight forwarder is recommended. They can offer detailed quotes based on your specific requirements and provide insights into potential additional costs.

Compare China and Other butterfly valve seal Markets: Products Quality and Price,Visible and Hidden Costs

When comparing butterfly valve seals from China and other markets, several factors emerge regarding product quality, price, and associated costs.

Product Quality

– China: Chinese butterfly valve seals are known for their broad range, from low to high quality. While there are high-quality manufacturers, many products are often of lower quality due to cost-cutting measures, leading to potential reliability issues.

– Other Markets: Manufacturers in Europe, the US, and Japan generally offer higher-quality products with rigorous standards and superior materials, leading to better durability and performance.

Price

– China: Chinese products are typically cheaper, benefiting from lower labor costs, economies of scale, and government subsidies. This makes them attractive for cost-sensitive projects.

– Other Markets: Products from Europe, the US, and Japan are more expensive due to higher labor costs, stringent regulatory standards, and higher quality materials.

Visible Costs

– China: Lower initial purchase price is a significant visible cost benefit.

– Other Markets: Higher initial purchase price reflects the superior quality and longer lifespan of the products.

Hidden Costs

– China: Potential hidden costs include higher maintenance, more frequent replacements, and possible downtime due to failures. Quality inconsistencies can also lead to additional testing and certification costs.

– Other Markets: Though initial costs are higher, hidden costs tend to be lower. High-quality products require less maintenance, fewer replacements, and less downtime, offering better long-term value.

Summary

Chinese butterfly valve seals offer cost advantages but may come with higher hidden costs due to variable quality. In contrast, products from other markets, while more expensive upfront, generally ensure better reliability and lower long-term costs. This comparison suggests that the choice depends on the specific project’s budget constraints and quality requirements.

Custom Private Labeling and Branding Opportunities with Chinese butterfly valve seal Manufacturers

Partnering with Chinese manufacturers for custom private labeling and branding of butterfly valve seals offers numerous advantages, primarily due to China’s established manufacturing infrastructure, competitive pricing, and expertise in valve production. Here’s how you can leverage these opportunities:

1. Cost Efficiency: Chinese manufacturers often provide competitive pricing due to lower labor and production costs, enabling you to maintain high profit margins while offering quality products.

2. Customization: Many Chinese manufacturers offer extensive customization options, allowing you to specify materials, designs, and branding elements. This flexibility ensures that the products meet your exact specifications and market requirements.

3. Advanced Technology: China’s manufacturing sector has significantly advanced, with many companies employing cutting-edge technology and automated processes. This results in high-precision and durable valve seals.

4. Scalability: Chinese manufacturers can typically handle large orders efficiently, making it easier to scale your business. Whether you’re looking to order a small batch for initial testing or large quantities for widespread distribution, these manufacturers can accommodate your needs.

5. Quality Control: Reputable Chinese manufacturers adhere to international quality standards, providing rigorous quality control measures. Many offer ISO certifications, ensuring that the products are reliable and meet global standards.

6. End-to-End Service: Many Chinese manufacturers provide comprehensive services, from initial design and prototyping to mass production and logistics support. This end-to-end service streamlines the supply chain, reducing the time and effort required to bring products to market.

7. Partnership Opportunities: Establishing a long-term partnership with a reliable Chinese manufacturer can lead to improved product innovation and mutual growth. Collaborative development projects can enhance your product offerings and keep you competitive in the market.

By leveraging these opportunities, you can enhance your brand’s market presence with high-quality, cost-effective butterfly valve seals customized to your specifications.

Tips for Procurement and Considerations when Purchasing butterfly valve seal

When procuring butterfly valve seals, consider the following tips and factors to ensure optimal performance and longevity:

1. Material Compatibility

Choose seals made from materials compatible with the media flowing through the valve. Common materials include:

– EPDM: Suitable for water and steam applications.

– NBR (Nitrile): Ideal for oil, gas, and fuel.

– Viton: Excellent for aggressive chemicals and high-temperature applications.

– PTFE (Teflon): High chemical resistance and suitable for a wide temperature range.

2. Operating Conditions

Ensure the seal can withstand the operating pressure and temperature. Verify the seal’s pressure rating and temperature range to match the valve’s specifications.

3. Seal Design

Select the appropriate seal design based on the application:

– Concentric: Ideal for low-pressure applications.

– Double Offset: Suitable for higher pressure and temperature.

– Triple Offset: Best for high-performance, high-pressure, and critical applications.

4. Sizing and Dimensions

Accurate sizing is crucial. Ensure the seal dimensions match the valve specifications to avoid leakage and ensure proper functioning.

5. Durability and Lifespan

Consider the expected lifespan of the seal. High-quality seals may have a higher upfront cost but offer longer service life and lower maintenance costs.

6. Manufacturer Reputation

Choose reputable manufacturers known for quality and reliability. Research customer reviews and request certifications if necessary.

7. Compliance and Standards

Ensure the seals meet industry standards and regulatory requirements. Look for seals certified by relevant authorities like ISO, ANSI, or API.

8. Cost-Effectiveness

Balance cost with quality. Cheaper options may reduce initial expenses but could lead to higher maintenance and replacement costs in the long run.

9. Availability and Lead Time

Check the availability and lead time of the seals to ensure timely procurement and avoid operational delays.

10. Technical Support and Warranty

Opt for suppliers offering technical support and a comprehensive warranty to address any potential issues.

By considering these factors, you can make informed decisions and select the best butterfly valve seals for your specific needs.

FAQs on Sourcing and Manufacturing butterfly valve seal in China

FAQs on Sourcing and Manufacturing Butterfly Valve Seals in China

1. Why source butterfly valve seals from China?

China offers competitive pricing, a vast manufacturing base, and a wide range of suppliers with varying capabilities. This can lead to cost savings and access to high-quality products.

2. How do I find reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Check supplier ratings, read reviews, request samples, and verify certifications such as ISO and CE.

3. What certifications should I look for?

Key certifications include ISO 9001 for quality management, CE for European standards, and specific industry standards like API for oil and gas applications.

4. What is the typical lead time?

Lead times vary by supplier and order size but generally range from 2 to 6 weeks. Custom designs or large orders may require longer.

5. How do I ensure quality?

Request samples, conduct factory audits, and specify material and performance standards in contracts. Third-party inspections can also be arranged through companies like SGS or Bureau Veritas.

6. What materials are commonly used?

Materials include EPDM, NBR, Viton, and PTFE, each suitable for different applications and environments. Ensure the supplier uses the appropriate material for your needs.

7. How can I manage logistics?

Work with freight forwarders or logistics companies experienced in international shipping. Ensure proper documentation, including commercial invoices, packing lists, and certificates of origin.

8. Are there any risks?

Risks include quality inconsistency, intellectual property concerns, and communication barriers. Mitigate these by thorough vetting, clear contracts, and using trusted intermediaries.

9. What about after-sales support?

Clarify warranty terms and after-sales service with the supplier beforehand. Reliable suppliers should offer support for defects or issues that arise post-delivery.

10. Can I visit the factory?

Yes, visiting the factory can provide insights into production processes and quality control. However, virtual tours and third-party audits are also viable alternatives if travel is not possible.